|

|

|

|

| News |

08.05.2017

Arrival of the Smart Dino

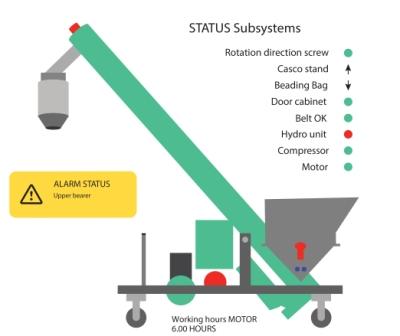

Van Beek, Drunen, the Netherlands, is currently in the process of integrating ‘smart’ features – including Industry 4.0 innovations – into its Dino mobile bulk truck loaders. To this end, the company is working in close association with Culemborg-based UVS Industry Solutions, a specialist in cost-saving smart maintenance and related smart industry technology. For example, the Dino is now being equipped with sensors to be able to predict when maintenance is necessary. “A logical next step is to equip machines with sensors that measure when a bearing actually needs replacing”, explained Eveliene Langedijk, director of UVS.

“It seemed a good match. Van Beek has long been toying with the question of how to apply Smart Industry and we soon agreed that the Dino is particularly suitable for this,” said Van Beek managing director Perry Verberne. This contributes to a better customer service and an improved Dino. Services are limited to a minimum because they will only be carried out when it is really necessary. Parts are replaced just in time. A further advantage is that the manufacturer is able to collect data on how the Dinos perform in the field and respond to this. For example, it may be ascertained that an electric motor is able to tackle a specific task much more easily than was previously assumed, allowing future Dinos can be equipped for the same application with a lighter and cheaper motor. Similarly it might be discovered that operators turn off the Dino far too often with the emergency stop instead of in the normal way, then Van Beek can point this out to the user in order to extend the machine’s life. www.van.beek.nl

The new Dino 4.0 and (below) schematic showing how machine performance can be monitored and when parts will need to be replaced

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|