|

|

|

|

| News |

11.02.2019

Powder Rheometer helps push AM to its limits

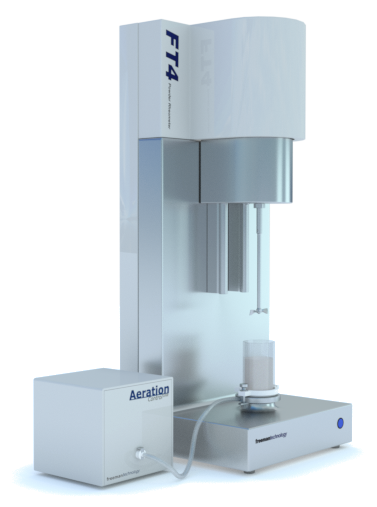

Freeman Technology, Tewkesbury, UK, recently supplied an FT4 Powder Rheometer® to 3D MicroPrint GmbH (Chemnitz, Germany), a company which is pioneering the use of additive manufacturing (AM) to produce complex, micro-scale metal parts. The FT4 is being employed to identify ultra-fine powders that will process efficiently. The company works with powders less than five microns in size to deliver components with cutting edge accuracy and resolution. The FT4 differentiates raw materials that exhibit the superior flow characteristics required for successful use of 3D MicroPrint’s micro laser sintering (MLS) technology, for applications in the medical, semiconductor, aerospace, energy and chemical industries.

“With MLS we are essentially pushing standard AM towards its performance limits,” said Joachim Goebner, CEO at 3D MicroPrint. “To achieve precise control at the micro scale we spread powders in layers just a few microns thick before selectively fusing areas of the powder bed with a highly focused laser beam. The ultra-fine powders required typically behave quite differently to powders of > 25µm particle size. We therefore rely on the FT4 Powder Rheometer to identify materials which will perform effectively with our machines, with specified process parameters. Before we had the instrument, selecting a suitable powder was essentially a matter of trial and error, a far less efficient approach.” www.freemantech.co.uk

FT4 Powder Rheometer

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|