15.04.2019

Soya milling process protected from metal particles

Eclipse Magnetics, Sheffield, UK, has supplied nine Pneumag magnetic separators to AB MAURI UK & Ireland, part of Associated British Foods, allowing the company to meet the very latest food safety standards in its soya milling processes. Fitted into pipelines that feed the soya beans into the process, the Pneumags provide protection against ferrous and para-magnetic contamination of dry powders and granulates.

Adrian Seeley, production supervisor at AB MAURI, said: “Our pipelines are angled, so the units supplied by Eclipse provide the perfect solution to replace the existing magnets. Our operatives have commented on how much easier these new units are to clean and inspect each week”.

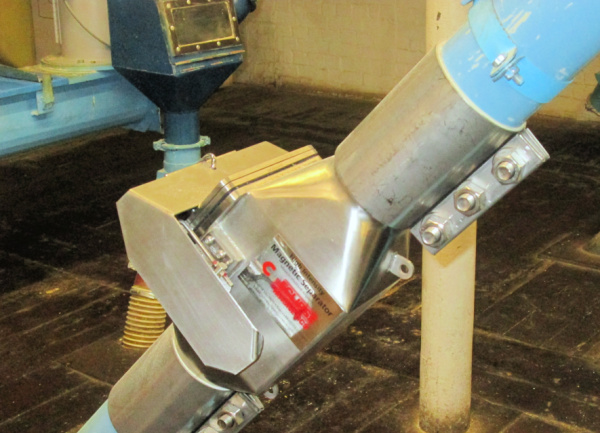

During milling, the soya beans are processed to a uniform particle size to produce flour. This is achieved by a sequence of breaking, grinding and separating operations. The high intensity magnetic separators ensure that even the smallest ferrous contamination particles are extracted from pneumatically fed lines. Each unit contains a double row high intensity magnetic cartridge, and is secured into its housing by quick-release toggle clamps, which ensure even pressure is generated around the unique silicon-based metal-detectable seal. The Pneumags were well suited for this application thanks to their ability to be installed at any angle, from vertical to horizontal. A lockable tamper-proof cover plate was also provided to ensure only authorised personnel are allowed internal access. www.eclipsemagnetics.com

The Pneumag can be installed into any angle of pipeline, from vertical to horizontal

« Back

|