17.06.2019

IBC blending – now with liquid addition

Matcon, Evesham, UK, points out that as consumer demand is continually changing, manufacturers must offer flexible and efficient production processes to stay ahead of their competition. Until now, if a powder blend required liquid addition, it was necessary to employ a fixed mixer, which can be difficult and time consuming to clean between recipe changeovers.

The company has invented and developed an innovative liquid addition system which expands the range of the IBC tumble blender and is well suited to industries that need the flexibility to add liquids into a wide range of powder recipe mixes in a contained and efficient manner. The system works by automatically injecting one controlled liquid ‘shot’ per rotation directly into the powder mix enclosed within the Matcon IBC during its blending cycle, without any need for manual intervention or to open the blending vessel. This ensures the even dispersion of liquids to a powder recipe during the mixing process, preventing lumps from forming.

Designed for manufacturers that need to deliver additions of liquids within the 5-150 litres range, this flexible and hygienic liquid addition system reduces manual handling requirements within the process and improves containment, further enhancing the benefits of IBC blending.

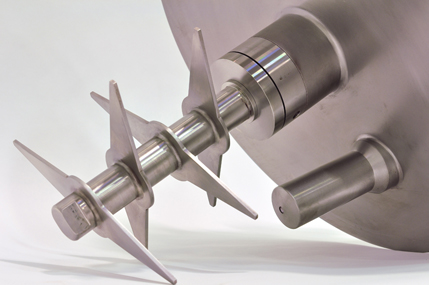

The system consists of a free-standing pillar supporting a reciprocating pump and weight monitoring system, on to which a liquid tank is mounted. These connect to the IBC via Matcon’s Liquid Additions Intensifier using tri-clamped hoses and a rotary coupling. The system also includes CIP flushing for neutral oils or cleaning fluids. www.matconibc.com.

Matcon’s new liquid addition feature on its IBC tumble blender

« Back

|