24.06.2019

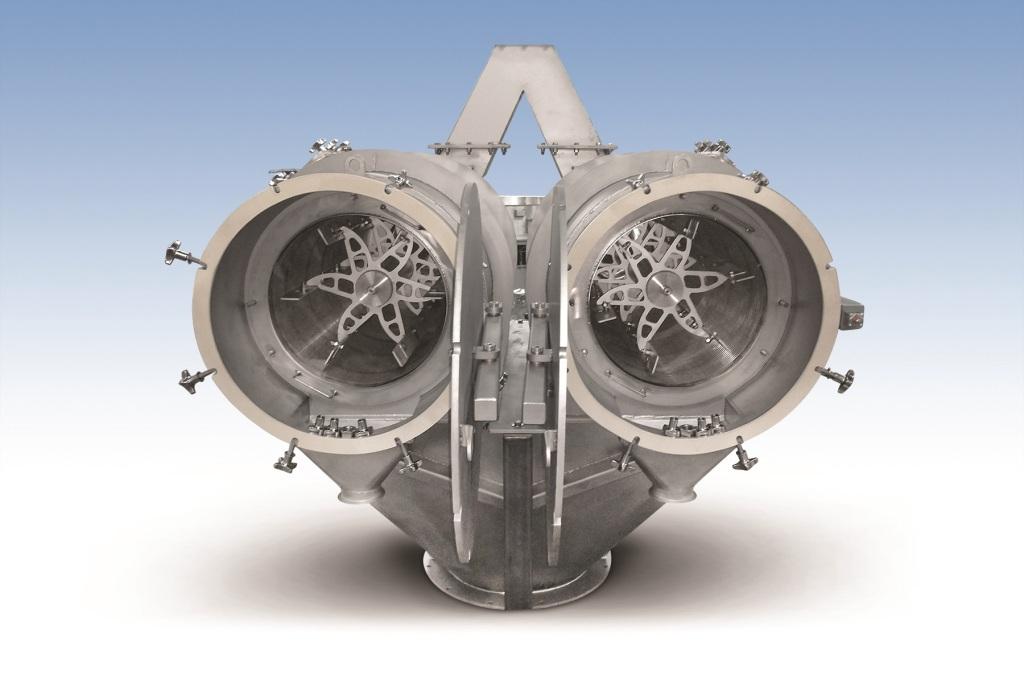

Twin in-line pneumatic centrifugal sifter

Kason Europe, Stoke-on-Trent, UK, has introduced a high-capacity dual centrifugal sifter which is designed to de-agglomerate and screen bulk materials in-line with dilute-phase pneumatic conveying systems at ultra-high rates. The model TWIN XOB-PS-SS PNEUMATI-SIFTER™ is rated up to 1 barg positive pressure and 356mm vacuum and delivers the capacity of two independent high-output sifters, while occupying less floor space.

A feed splitter evenly divides the flow of incoming material into two horizontal cylindrical screening chambers operating in parallel. A shaft within each screening chamber rotates a helical paddle assembly that accelerates the radial movement of particles and soft agglomerates against and through the screen. The design allows all internals to slide freely from the shaft ends for cleaning, screen changes, or inspection. Wide spacing between the bearings, a large diameter shaft, and a flexible shaft coupling combine to prevent vibration, even at high speeds under heavy, imbalanced loads.

Available in compliance with FDA, 3-A, BISSC, EEC and other European and US sanitary standards as well as ATEX compliance, the sifter is fabricated from stainless steel finished to sanitary standards. Optional clean-in-place (CIP) nozzles make it suitable for food, dairy, pharmaceutical and contamination-sensitive industrial applications. The machine is manufactured at the parent company’s US factory. www.kasoneurope.com

Kason’s new PNEUMATI-SIFTER operates in line with positive or negative pressure pneumatic conveying systems; each screening chamber (below) has been designed to facilitate rapid screen changes, cleaning and inspection

« Back

|