|

|

|

|

| News |

15.07.2019

Magnetic separator specialist gains coded welding approvals

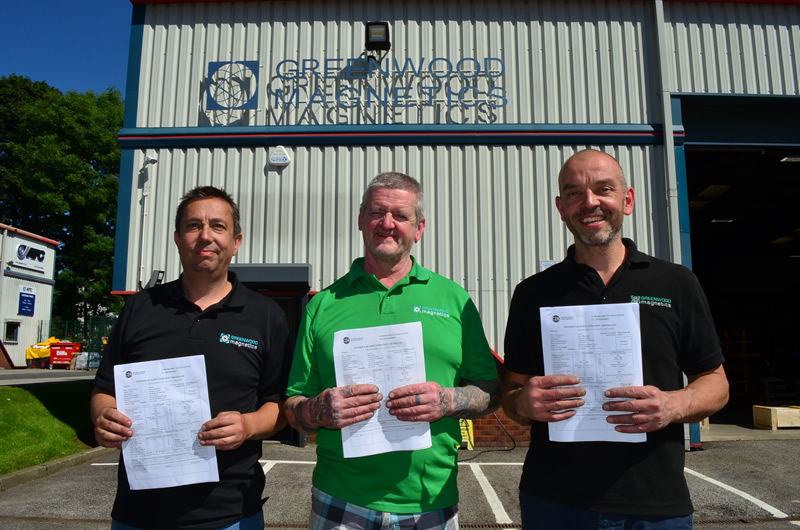

Greenwood Magnetics, Rochdale, Lancashire, UK, reports that three of its senior sheet metal workers have been assessed and certified in coded welding for high-pressure applications. As the company’s products are bespoke and manufactured to client specification, it needs to be ready to meet specific requirements.

“One of our clients required a high-pressure application with magnetic separators welded to a specific code and procedure. Naturally, we were happy to help,” commented managing director Jeremy Greenwood. Despite demanding timescales for the project, the welding team embraced the challenge of having their skills assessed and examined to the highest international standards. All three passed at the first attempt. They are now fully certified to weld to BS EN ISO 9606 and work to welding procedures under ISO 15614. www.greenwoodmagnetics.com

The three Greenwood Magnetics staff with their coded welding certificates

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|