29.07.2019

WIP process in horizontal mixing systems

Gebr. Lödige Maschinenbau, Paderborn, Germany, reports that an efficient cleaning process for horizontal mixing systems is becoming increasingly important. Nowadays, hygienic requirements are no longer limited to the pharmaceutical industry. An integrated cleaning system is today frequently requested by customers for new mixers used in the food, cosmetics and chemical industries. A key concern is the prevention of cross-contamination by allergens, flavours and active ingredients during product changeovers as well as the elimination of potential microbiological contamination.

In general, cleaning systems for process-related equipment can be divided into two categories: semi-automatic WIP systems (wash-in-place) and fully automatic CIP systems (clean-in-place). The latter does not require any manual cleaning steps. Horizontal mixing systems generally use a WIP system, since minor manual steps, such as removing a filter or installing a drainage cone on the machine outlet, are frequently required. Chemical disinfecting of the system can be performed after machine cleaning, where required. This is referred to as an SIP system (sterilisation-in-place).

The cleaning process itself comprises the residue-free removal of any remaining product and material build-up on the entire mixing drum. For this purpose, the air purged seals of the mixing shaft and choppers will be flushed with water to prevent ingress of cleaning water into the seals. Afterwards, the horizontal mixer is cleaned progressively from top to bottom. For this purpose, all sockets on top of the machine are equipped with cleaning nozzles, which are either firmly welded on the inside of the socket or can be positioned on the socket as a separate washing adapter. It is also possible to install automated retractable cleaning nozzles. www.loedige.de

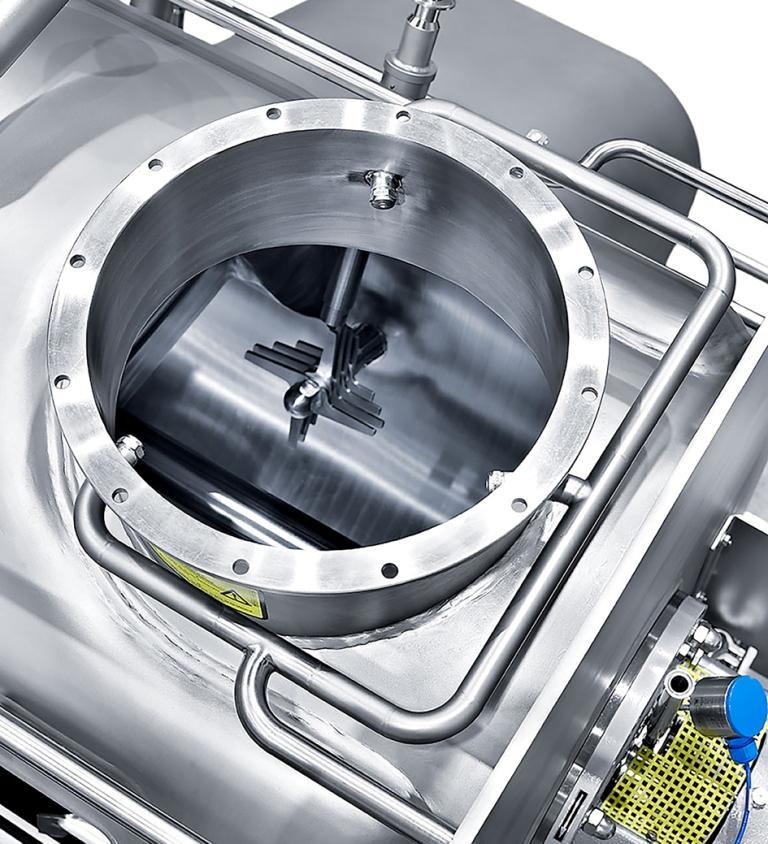

Example of a Lödige feeding socket with fixed cleaning nozzles and flushing capability

« Back

|