|

|

|

|

| News |

23.09.2019

Hot-wash system for effective plastic recovery

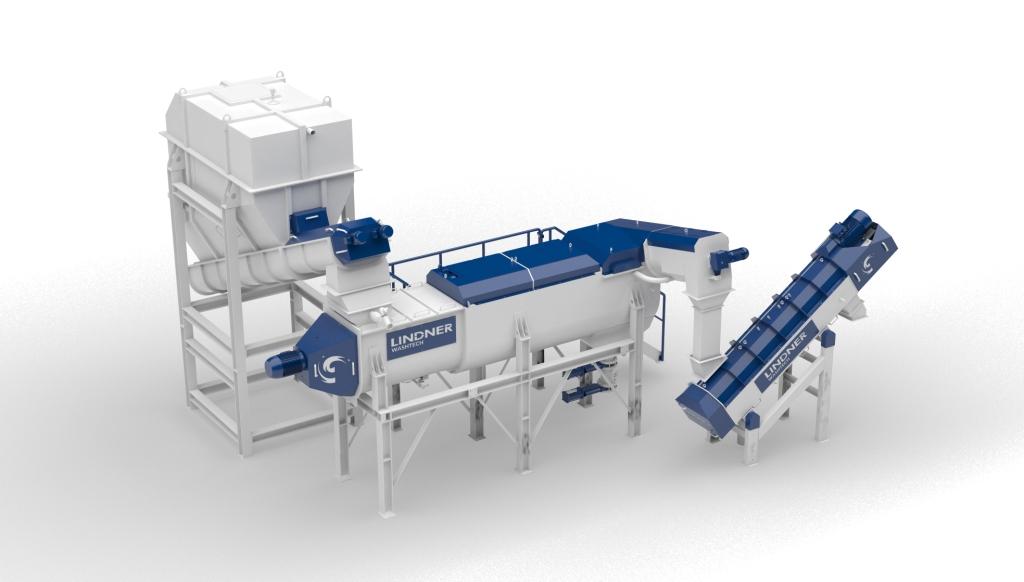

Lindner Washtech – the German subsidiary of Austria’s Lindner Recyclingtech – has developed a three-stage hot-wash system which is capable of cleaning undesirable materials adhering to post-commercial and post-consumer plastic film, as well as unpleasant odours; it also ensures higher productivity.

The modular and compact Lindner hot-wash system has three stages and does not require any additional conveyors. In the first stage, the shredded and pre-washed plastics are fed into a reactor, mixed with hot water and washed. Already at this stage, mixing arms apply concentrated friction to the material. The double discharge screw conveyor then feeds the plastics into the new hot-wash rafter in optimally dosed quantities. This is a new and improved version of the already successful rafter pre-washer, in which continuous friction is applied to the material to remove and separate residues effectively and gently. In the third and final stage, the Twister friction washer, a machine specifically designed for this application, removes the hot water or the hot caustic solution. The liquid is then separately treated.

Optionally the system can also be operated with caustic solution to remove even stubborn fat and oil residues, as well as glue. The downstream water treatment system continuously monitors the water’s alkaline content and automatically applies the necessary chemicals. The system will be exhibited at the K Show. www.lindner.com; www.lindner-washtech.com

The new Lindner Washtech hot-wash system cleans effectively in three stages and guarantees continuous output

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|