23.09.2019

Italian compounder upgrades pilot plant

Coperion, Stuttgart, Germany, has won a contract to supply Italy-based family-owned compounder LATI Industria Termoplastici SpA with the pre-engineering and engineering of a state-of-the-art materials handling line for a pilot plant at its production site at Torba (Varese), Italy.

The focus of this project is on the development of a tailor-made solution for the semi-automated and automated materials handling of raw materials for the extruder. A key challenge is the broad variety of different raw materials with variable properties, which requires a high flexibility of the plant design. Quick changeover times are required to increase the overall efficiency of the plant. Moreover, processes such washing, cleaning and the fast removal of the equipment to facilitate short changeover times needed to be considered and streamlined from a technical viewpoint; quick clean solutions are needed to improve and shorten the processes. This pilot plant is a key step for LATI's factory of the future, including automation and digitalisation of the entire production process.

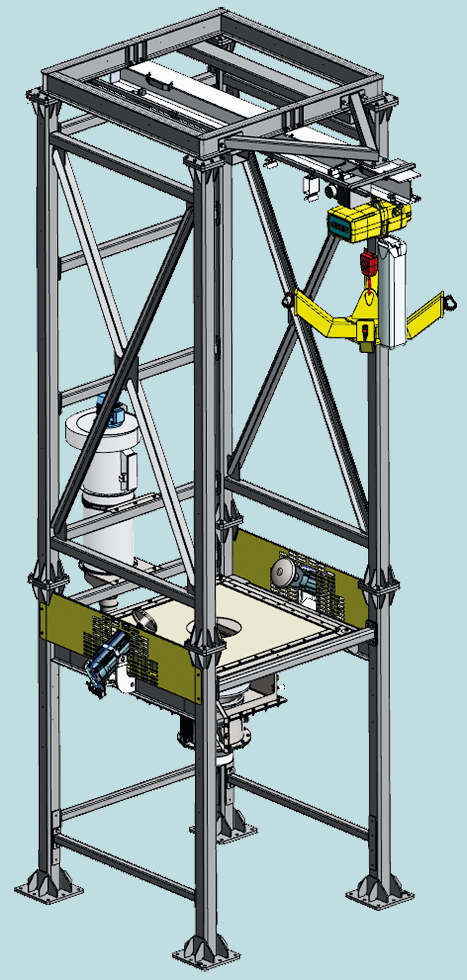

Together with LATI’s technical staff, Coperion developed an overall materials handling concept including innovations like the new versatile multi-tasking BES-6 bulk bag discharge station for free flowing and sticking materials with an easy-cleaning concept, modular design for adaptable configuration, and a flexible interface. In addition, the scope of the project includes bulk bag unloading and weighing stations as well as vacuum conveying lines managed by a unique aspirator. The materials handling equipment is designed to easily interface with the existing Coperion K-Tron feeders of the pilot plant. The data exchange for raw material consumption and management in real time meets Industry 4.0 standards as well as the process optimisation measures. Safety standards and ergonomics are of utmost importance to LATI and the pilot plant will be built accordingly. www.coperion.com

Coperion’s new BES6 bulk bag discharge station for free flowing and sticking materials with an easy-cleaning concept, modular design for adaptable configuration, and a flexible interface will be a key feature of the pilot plant

(Below) The pilot plant’s project team: Andrea Lugli, director of operations, LATI; Emanuele Falavena, sales manager, Coperion Italy; Dr Michela Conterno, CEO of LATI; Lorenzo Lambertini, LATI engineer; and Massimiliano Baroffio, LATI, electrical maintenance engineer

« Back

|