20.01.2020

VERDER Group companies merge to form Microtrac Retsch

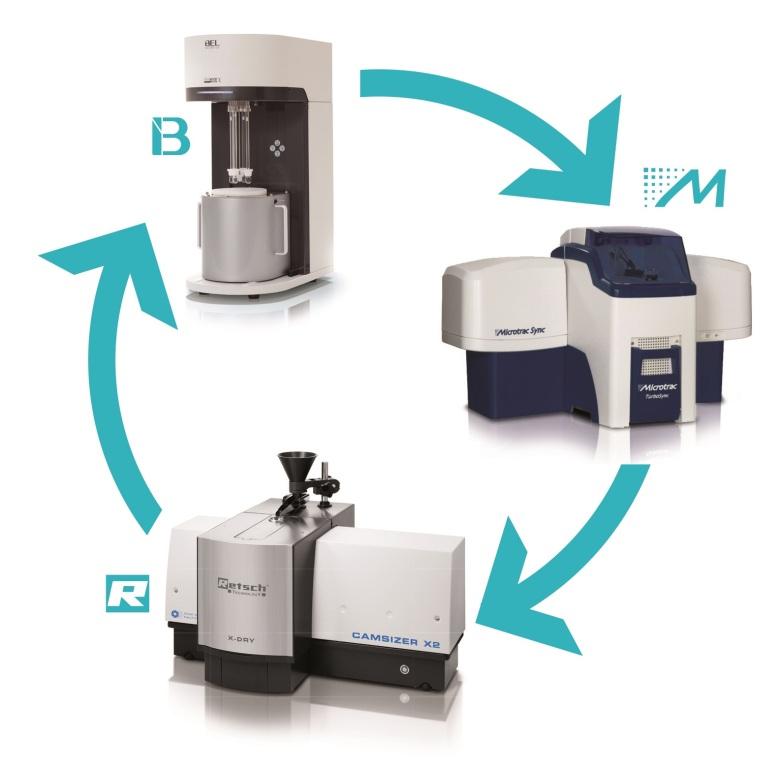

On 1 January the companies RETSCH Technology GmbH, Microtrac Europe GmbH and BEL Europe GmbH joined forces to become Microtrac Retsch GmbH. This new company will enable users of particle characterisation in the EMEA region to access the broadest product portfolio worldwide from one single source. Under the brand name Microtrac MRB the company provides systems for particle characterisation by laser diffraction, dynamic light scattering, dynamic and static image analysis, as well as gas adsorption measurement to determine specific surface and pore size distributions.

RETSCH Technology has been part of the VERDER Group since its foundation in 1998 and has revolutionised the market for particle characterization with dynamic image analysis by developing the dual camera technology implemented in the CAMSIZER series.

The manufacturing companies Microtrac Inc. (USA) and MicrotracBEL (Japan) were acquired by VERDER in July 2019. This resulted in the formation of a new global player under the roof of the VERDER Group which aims to become a technological leader in particle characterisation.

Microtrac Retsch has its head office in Haan near Düsseldorf/Germany, on the premises of the VERDER SCIENTIFIC division. The companies RETSCH, Carbolite Gero, Eltra, ATM and Qness are also part of this division. www.microtrac.com

Microtrac Retsch provides instruments for particle characterisation based on laser diffraction, dynamic light scattering, dynamic and static image analysis and gas adsorption

« Back

|