|

|

|

|

| News |

18.02.2013

Screen changers for food packaging film production

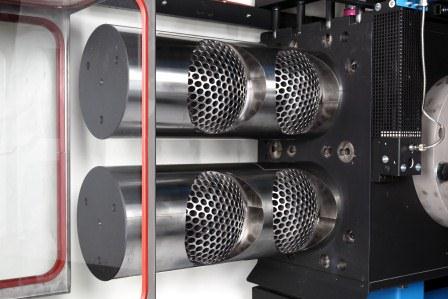

Following successful trials at the plant of a South American food packaging film manufacturer, Kreyenborg, Münster, Germany, has equipped eight of the company’s recycling lines with backflush screen changers. Through the filtration process, PET flakes can be processed at a throughput rate of 500kg/h, though different qualities of material and varying degrees of contamination pose a challenge for the screen changers.

To give an estimate of the running costs (loss of material due to backflushing, wire screen cloth, etc), eight of the Kreyenborg screen changers were compared against a currently available screen wheel filter which was in use on an identical extrusion line. During the processing of various different materials, the amount of material lost hourly as a result of the backflushing operation using the Kreyenborg equipment was reduced by half compared with the screen wheel filter. Furthermore it was possible to increase the fineness of the filter mesh. The customer plans to order two additional backflush screen changers during the coming months. www.kreyenborg.com

Kreyenborg backflush screen changer

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|