|

|

|

|

| News |

10.08.2015

Integrated mixing system includes emptying/filling of containers

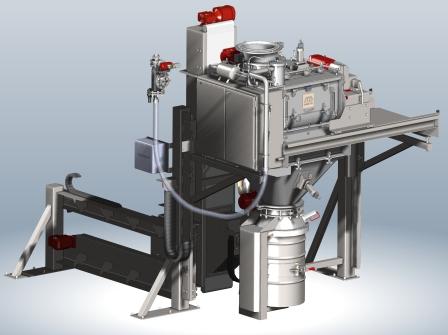

Dinnissen, Sevenum, the Netherlands, has launched a compact and advanced ‘All-in-One Mixing’ concept which lifts, tilts, empties, mixes, and fills containers from a single location. It is especially suited for situations where it is important to prevent contamination and to quickly and easily switch between recipes.

The operator places a drum or other container with all the necessary ingredients in a special lift. The lift raises the drum and is then hermetically linked to the overall system within a particle-free environment. The drum then tilts automatically and is connected to the mixer, after which a special clean-air system completely empties it into the double-shaft Dinnissen Pegasus® Mixer, without leaving any residues behind. There, the ingredients are gently suspended and mixed extremely quickly and thoroughly. After the mixing process, the container that was originally fed into the system and has been emptied, without leaving any residue behind, is automatically filled with the end product. This latest innovation will be exhibited by the company, together with its new easy-to-clean sampling system (see last week’s EBS News) at SOLIDS Rotterdam at the end of September and at SOLIDS Dortmund in early November. www.dinnissen.nl

A double-shaft Pegasus Mixer forms an integral part of the new all-in-one concept

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|