30.05.2022

Innovations at CERAMITEC [2]

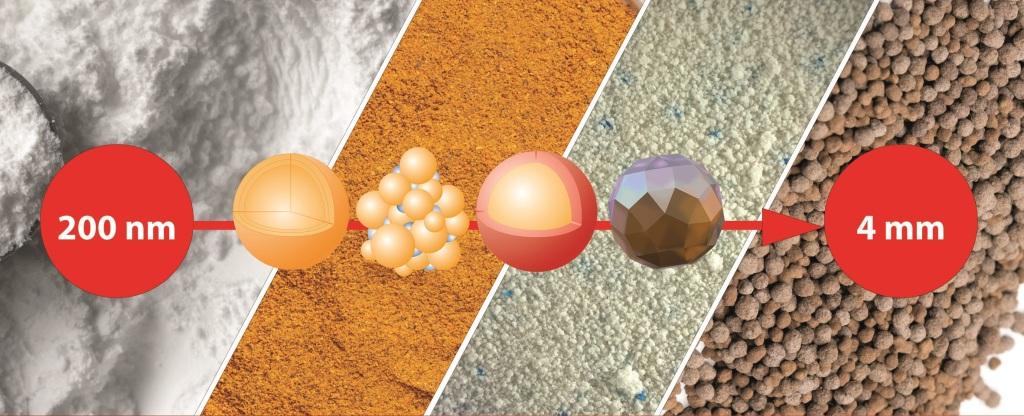

Glatt Ingenieurtechnik, Weimar, Germany, will also be at CERAMITEC (see above), showcasing its technology for powders and granules with special properties for bioceramics, industrial ceramics, LED applications and batteries for electromobility. From nanometres to millimetres, Glatt (Stand 409, Hall C2) will be demonstrating its expertise in particle design for grain sizes from nano to macro. At the leading international trade fair for the ceramics industry, the fluid bed and spouted bed pioneer will present these technologies as well as its processes in the pulsating gas stream of powder synthesis.

By combining drying, granulating, coating and calcining in a single step, the process expert and plant manufacturer facilitates the efficient handling of solid and liquid starting materials at process temperatures from 40 to 1300°C. In addition, Glatt partners with its customers from product idea to production and also offers technology transfer, and services for process and plant engineering, contract manufacturing and factory planning for functional powders, granules and pellets.

With their wide range of process options, Glatt technologies are said to provide almost unlimited possibilities for optimum particle design and the functionalisation of bulk material particles. The key to the ideal product lies in the optimised selection and combination of the most appropriate process parameters.

Thanks to the particularly homogenous thermal treatment at up to 1300°C, ultrafine powders produced using the pulsating gas stream of Glatt’s powder synthesis technology have no undesirable hotspots or hard aggregates and are easy to disperse. Further advantages include the very high heat and mass transfer rates in the reactor and the ability to specifically determine the layer thickness, porosity and activity profiles of powder particles.

Fluid bed and spouted bed processes transform powders and liquids into dustfree, free flowing granules and pellets that can be precisely dosed and safely handled. Particle coatings and microencapsulation guarantee the protection of bulk solids and the environment, thereby ensuring greater storage stability. They also improve sensory appeal and enable the retardation and controlled release of active ingredients.

Glatt’s customers can benefit from access to innovative technologies, very short development times for new particle shapes and seamless scale-up based on laboratory and pilot trials conducted at the company’s own technology centre in Weimar. www.glatt.com

Glatt particle design from nano to macro will be featured at CERAMITEC in Munich

« Back

|