|

|

|

|

| News |

04.04.2016

High-capacity Z-conveyor offers safety advantages combined with major cost savings

Poeth Solids Processing, Tegelen, the Netherlands, has recently developed an innovative and cost-effective Z-Conveyor for high-capacity transport of bulk solids to great heights. In contrast to conventional bucket elevators, the Z-Conveyor eliminates the need for expensive investments in ATEX safety equipment. The new conveyor is also energy-efficient and suitable for handling fragile products. Moreover, the construction costs are also said to be significantly lower.

According to Poeth, the cost of ensuring that traditional bucket elevator systems are adequately protected from risk of dust explosions can be up to three times as much as the cost of the bucket elevator itself. The company points out that dry organic particulates are by nature potentially explosive, especially when transported at speeds in excess of 1m/s. Although bucket elevators are very suitable for transporting materials vertically, Poeth suggests that such systems are effective only at speeds in excess of 2m/s. Accordingly, bucket elevators must be equipped with increasingly rigorous and expensive ATEX-compliant safety measures. The innovative design of the new Z-Conveyor developed by Poeth allows for high loading levels and transport capacities from 45m³ up to 220m³ per hour. Since the Z-Conveyer has excellent performance characteristics at speeds well below 1m/s, there is also minimal risk of explosion. This eliminates the need for making major investments in order to ensure compliance with the increasingly strict ATEX safety standards, including the costs resulting from the new CEN 305 legislation. www.poeth.nl

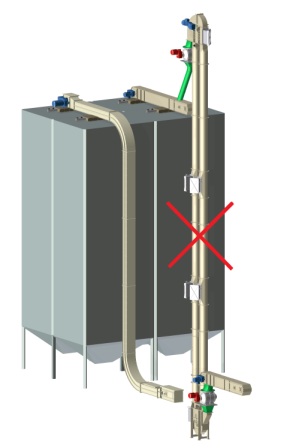

Poeth Z-Conveyor (left) alongside a conventional bucket elevator

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|