|

|

|

|

| News |

07.11.2016

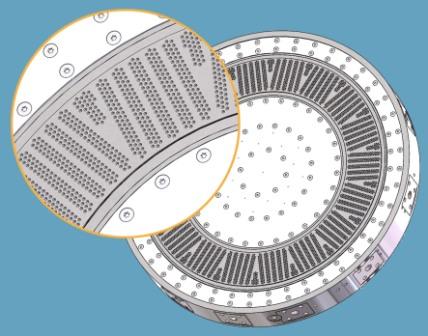

Underwater pelletizer offers increased wear protection

Coperion, Stuttgart, Germany, introduced the die plate of its new UG 750W underwater pelletizer at K 2016 in October. Designed for producing polyolefins and capable of achieving throughputs of 60-70t/h, the new pelletizer serves medium capacity requirements. Its large die plate will be manufactured from a newly developed material which is highly resistant to both abrasion and corrosion and can double service life.

The UG 750W pelletizer is an economically attractive solution which bridges the existing gap in capacity between the UG750 with its maximum throughput of 55t/h, which is very widely used in PE applications, and the much larger UG1000 for throughputs of up to 82t/h. Based on the UG750, the new machine is equipped with the extended cutting surface from the UG1000. Thus, the system makes use of components which have proved reliable over many years both for the die plate/blade system (UG1000) and for the mechanical components blade shaft bearing, pelletizer hood and drive train (UG750). Thanks to the wider cutting circle and an optimised arrangement of the die holes, it has been possible to increase the number of holes in comparison with the UG750 by just about 27% to over 5700 and so achieve the desired increased throughput. www.coperion.com

The UG 750W’s die plate will be fabricated from NikroDur, a wear protection material which Coperion has jointly developed with DEW Deutsche Edelstahlwerke

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|