18.02.2019

Single compact machine mixes, coats, dries and roasts

Lindor, Dordrecht, the Netherlands, recently supplied a purpose-designed mixer with additional coating, drying and roasting capabilities to a German company which specialises in processing exotic fruit. “The company needed a more efficient way to produce the sweetened fruit flakes," explained Michael Kaiser, Lindor's sales manager Germany. “The caramelised flakes proved to be a popular product, but the earlier caramelisation process was very labour-intensive and time-consuming.

"During the decades that we have been producing mixers, we have noticed that our mixers are a great platform for doing more than simply mixing. Before long, a customer asked us whether it would be possible to spray liquid on to the product during the mixing process. And, some time later, another customer asked if we could dry the contents. Over time, what began life as a mixer, had crystallised into a versatile processing machine.”

This experience enabled Lindor to produce a mixer for its new customer that mixes the larger and smaller flakes in a short period of time. A special nozzle at the inlet then sprays a sugar solution over the flakes. Because the mixer continues to rotate, the flakes are sprayed from all sides, giving them a perfect coating.

After applying the coating, warm recycled air is blown into the mixer. The air blows against the flow of the product to maximise heat transfer. The moisture released during the drying cycle, escapes via the vent on the inlet side. Once the moisture has been expelled, the air temperature is raised and the flakes are roasted, resulting in the desired golden brown caramel layer.

Usually, Lindor mixers are part of a processing line, but in this case this one machine covers the entire process. Bags of flakes are emptied into the mixer which then completes the programme, and an hour later the caramelised flakes flow out. In the past not only a mixer would have been required, but also a belt conveyor with spray tunnel and an oven to complete the process. www.lindor.nl

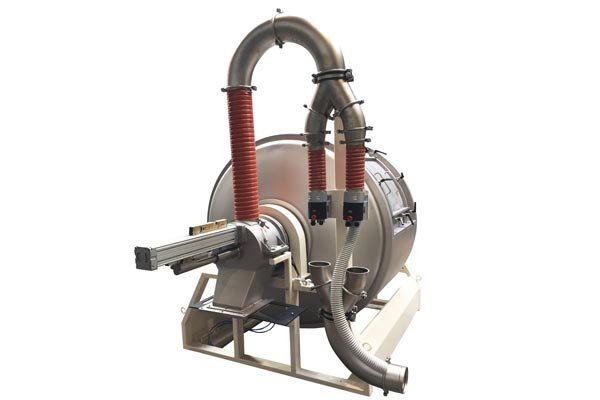

The Lindor multi-purpose machine; the most challenging aspect of this project was the delicacy of the flakes and the time needed to roast them properly – tests showed than the flakes, even after a long run, all emerged from the machine intact

« Back

|