18.02.2019

Phosphorus recycled from ash to produce quality fertilisers

Glatt Ingenieurtechnik, Weimar, Germany, will be presenting a market-ready process at POWTECH (Stand 3-249) that fulfils the legal obligation of German waste disposal companies to recover phosphorus. In the first step of the two-stage ‘PHOS4green’ process, a suspension is produced from the phosphate-containing ash, a mineral acid and – depending on the objective – other components. The suspension is then spray granulated in a fluidised bed. This results in fertiliser granulates which can be discharged, filled and delivered directly after the desired grain size has been reached.

"Fluidised bed granulation has been a mature process for decades, enabling a simple and safe introduction to fertiliser ordinance-compliant phosphate recovery," said Lutz Heinzl, sales manager, food, feed and fine chemicals at Glatt. "The process recycles 100% of the ash. By flexibly adapting the recipes, a wide variety of fertilisers, including complex varieties (NP, PK, NPK), can be produced, which can be placed on the market as new products."

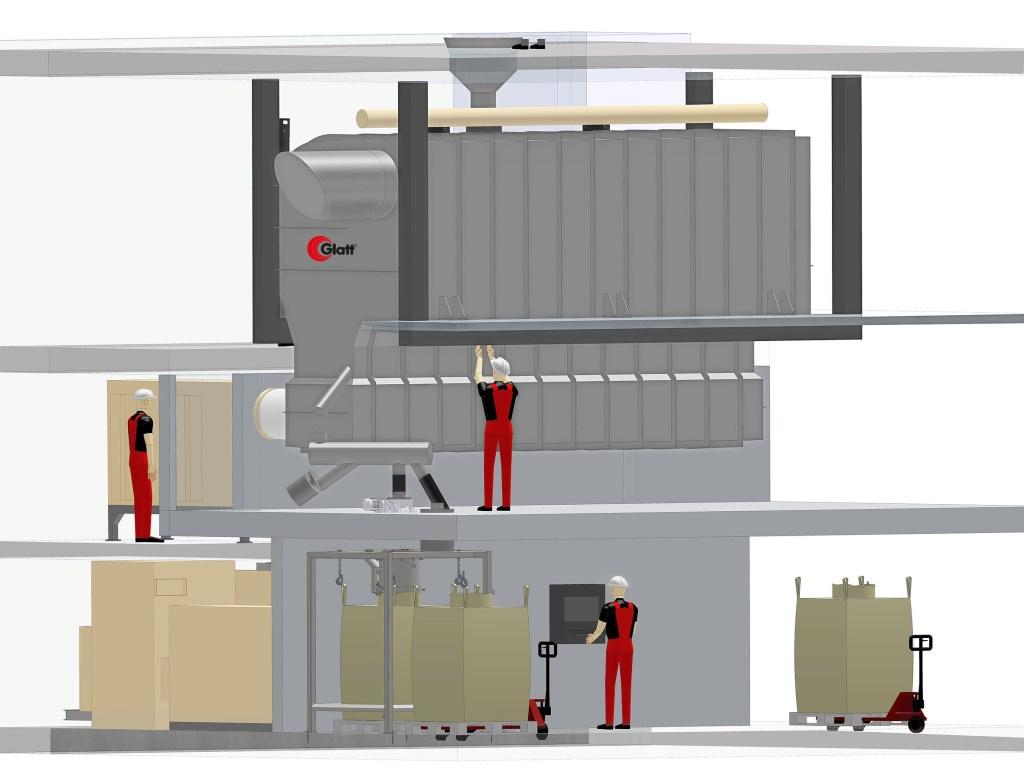

Transforming fine powders and powder mixtures into uniformly porous, practically dustfree, soluble and meterable granulates is what the new GF-ModFlex plant concept achieves in an endless loop with consistently high quality and safety. The process is based on established Glatt fluid bed technology and, thanks to gentle process control, preserves the nutritional and functional properties of the products. With this compact modular system, the company is responding to manufacturers who want to upgrade or renew their machinery at short notice, with limited space and with production volumes in the range 100–3000kg/h. www.glatt.com

Typical layout of the Glatt GF-ModFlex system

« Back

|