|

|

|

|

| News |

01.07.2019

Rotary valves in tandem with magnetic separator

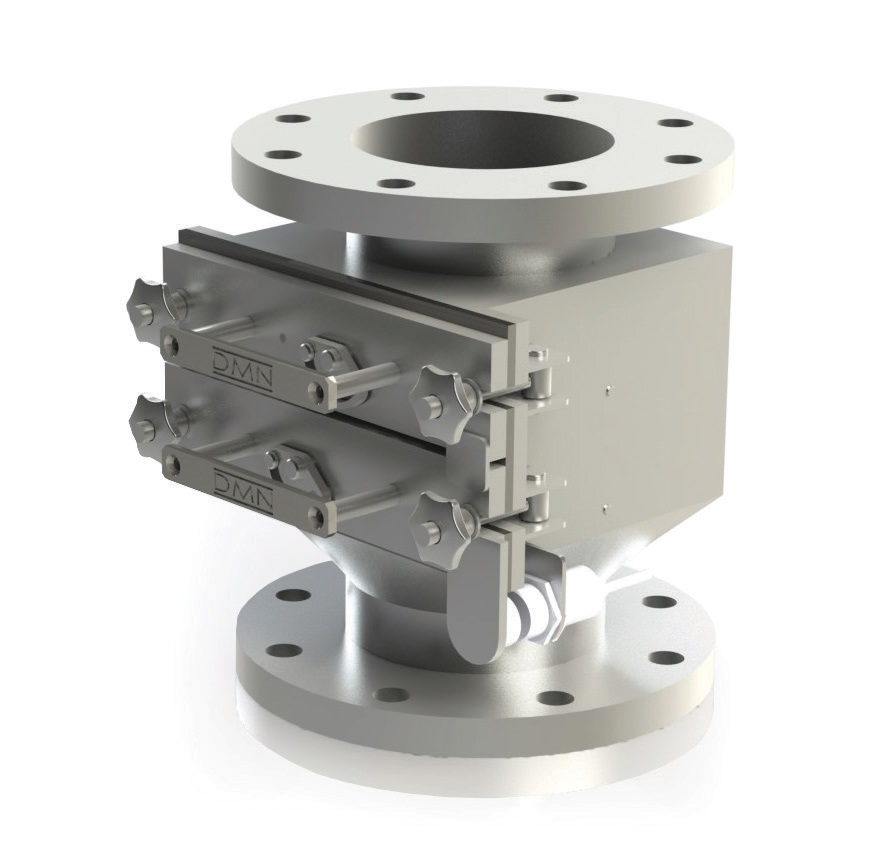

DMN-Westinghouse, Noordwijkerhout, the Netherlands, a leading manufacturer of rotary valves and diverter valves, recently introduced a range of magnetic separators designed to remove sub-micron metal contamination (including particles of 304 and 316 stainless steel) from dry, free flowing products such as sugar, grain, flour and other granulates and powders during processing.

Metallic contamination can ultimately lead to a batch of expensive ingredients having to be destroyed. Therefore, the removal of these particles is vital. However, an additional concern is the effect that metallic contamination can have on rotary valves and other processing machinery. The DMN magnetic separators will help increase the life of rotary valve vanes and blades by preventing metal contamination from entering the unit in the first place and causing damage. The ideal location for a DMN magnetic separator is as close to the rotary valve as is practical.

The easy-clean design allows DMN magnetic separators to be safely and quickly cleaned by removing the magnetic cores from their fully welded 316 stainless steel tube housings. The DMN specification comes with interlock switches as standard to prevent any possibility of injury being caused by opening the magnet. All units can be ATEX certified for use in Zones 20, 21 and 22 or in gas Zones 0, 1 and 2 so will not affect the APS ATEX certification of a rotary valve or other equipment. DMN UK reports that it has just made available its first magnetic separator demonstration unit. www.dmnwestinghouse.com

DMN magnetic separator

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|