07.10.2019

Promoting flow by ultrasonic excitation

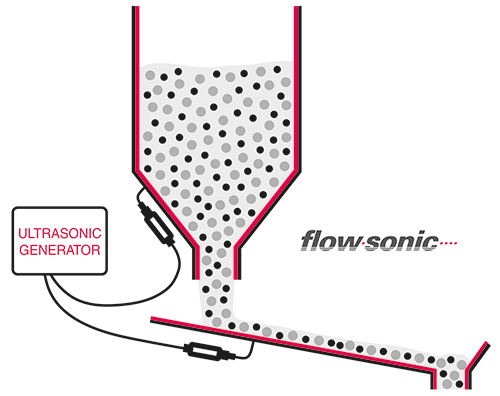

Artech Ultrasonic Systems, Bottighofen, Switzerland, recently launched the flowsonic® ultrasonic discharging aid which ensures efficient flow of powders and granulates, whether being conveyed or stored in containers, bins or hoppers. This solution – which offers an energy-saving and low-noise alternative to mechanical and pneumatic flow-promotion aids – can be customised depending on the product and equipment characteristics in question. Classic flow problems such as bridging, ratholing and segregation can also be prevented.

In bulk materials handling, ultrasonic is a recognised approach to reducing the friction forces between the particles and the screening mesh, for example. Thus, in screening machines, the powder flowability can be enhanced by means of ultrasonic. A novel approach is to apply ultrasonic to the walls of the bulk handling equipment, whereby the static and dynamic friction forces are influenced for optimised discharging, feeding and dosing.

The best results in terms of throughput and cleaning effect are achieved with dry bulk materials or those with low moisture content. Application of ultrasonic is not suitable for oily or greasy bulk materials. On the other hand, pneumatic and mechanical flow aids are completely unnecessary for powders that react well to ultrasonic in bulk materials handling equipment with polished inner walls. The walls should not exceed a thickness of 5mm. It is also important to have a sufficient angle of inclination for sonicated conveyor channels and pipes; this should be at least 5°. The investment costs for an ultrasonic system as a flow aid may be higher than for mechanical or pneumatic solutions. However, these costs usually pay off within a short period of time: Ultrasonic generators typically operate with power outputs of up to 120W.

In the classic method, the frequency of the geometry must be tuned to the frequency band of the ultrasonic generator. A pronounced resonance with a small resonance width must be available for the resonance excitation to be efficient. In the case of bulk material containers, pipes, conveyors or complex structures, resonance tuning is almost impossible. Artech Ultrasonic Systems has developed and patented the frequency variation method as a solution. Instead of stimulating a defined resonance, the ultrasonic generators vary within an adjustable frequency range. Ultrasonic is thereby flexibly applicable to various geometries. www.artech-systems.com

Ultrasonic flow aid: reduction of static and dynamic friction

Ultrasonic discharging and conveying

« Back

|