08.06.2020

Cosmetics producer opts for safe and quick mixing

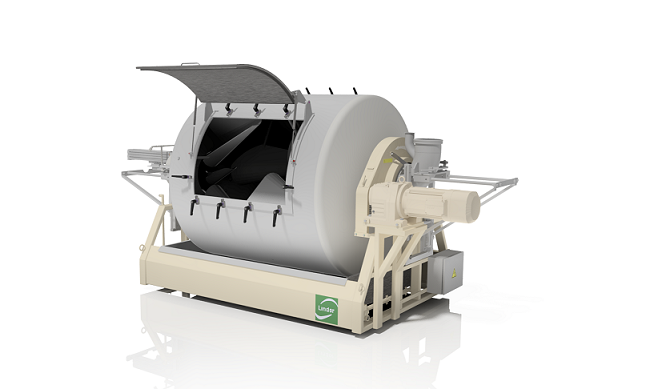

Lindor, Dordrecht, the Netherlands, recently supplied an L1500 mixer to a manufacturer of special cosmetics, where the Dutch equipment manufacturer’s unique gentle-touch technology was able to provide a perfect system for blending sensitive substances.

The mixing machine is at the heart of production. It ensures that different ingredients, such as fine powders, granulates and natural products, are well mixed and processed into the required end product. Very sensitive, fragile products require a different method of processing that uses natural gravity without the risk of breakage, heat or smearing by friction.

Thorough and quick mixing can be dangerous when working with sensitive or even explosive substances, as in this case. As there were doubts about the quality and safety of the installed traditional mixers, the customer was looking for a new technique that would make the production of these particular powders even safer.

The customer operates several factories in Latin America, but only the plant in question is capable of producing these special cosmetic products. The town stands at an altitude of about 2500m, which translates into a relatively cool and dry climate.

The Lindor L1500 mixer has been equipped with two liquid injectors, allowing a perfume to be added to the powder to counteract the chemical smell; addition of a second liquid serves to compact the powder and improves handling.

Since the Lindor L1500 was commissioned, the production process has become approximately an hour quicker. Time savings are gained mainly in the cleaning of the mixer and changing of the colouring powder. “A job which previously took us two days can now be done in four hours,” said the operations manager.

The mixer has a CIP (cleaning-in-place) configuration. This means that it does not need to be opened but cleans itself automatically at the touch of a button. The operations manager also intends to replace another manufacturer's traditional mixer with a second Lindor L1500 at some point between 2020 and 2021. This will include additional liquid injectors and a Pt100 temperature sensor. www.lindor.nl

Lindor ‘gentle touch’ mixer

(Below) CIP allows the mixing chamber to be kept clean without manual intervention

« Back

|