14.09.2020

Gentle compounding combines efficient mixing with good scalability

Buss AG, Pratteln, Switzerland, is celebrating three quarters of a century specializing in manufacture of continuous kneaders which operate in accordance with a principle patented in 1945. Convinced at the time by the concept, Buss inaugurated the first kneader test centre in 1948 and delivered the first compounding systems for PVC and polystyrene in 1950. The company subsequently established this technology globally as the system of choice for producing compounds both efficiently and particularly gently.

To date, Buss has produced over 3500 of these compounding systems, exporting them to over 80 countries. Applications range from compounding high-performance engineering polymers with temperature- or shear-sensitive components, such as electrically conductive carbon blacks with filler contents as much as 90% or more, to the production of formulations for the aluminium, chemicals and food processing industries. Buss's current range of compounding extruders for the plastics and elastomer industry includes the COMPEO series which is available in six sizes and is capable of processing up to 12,800kg/h of thermoplastics.

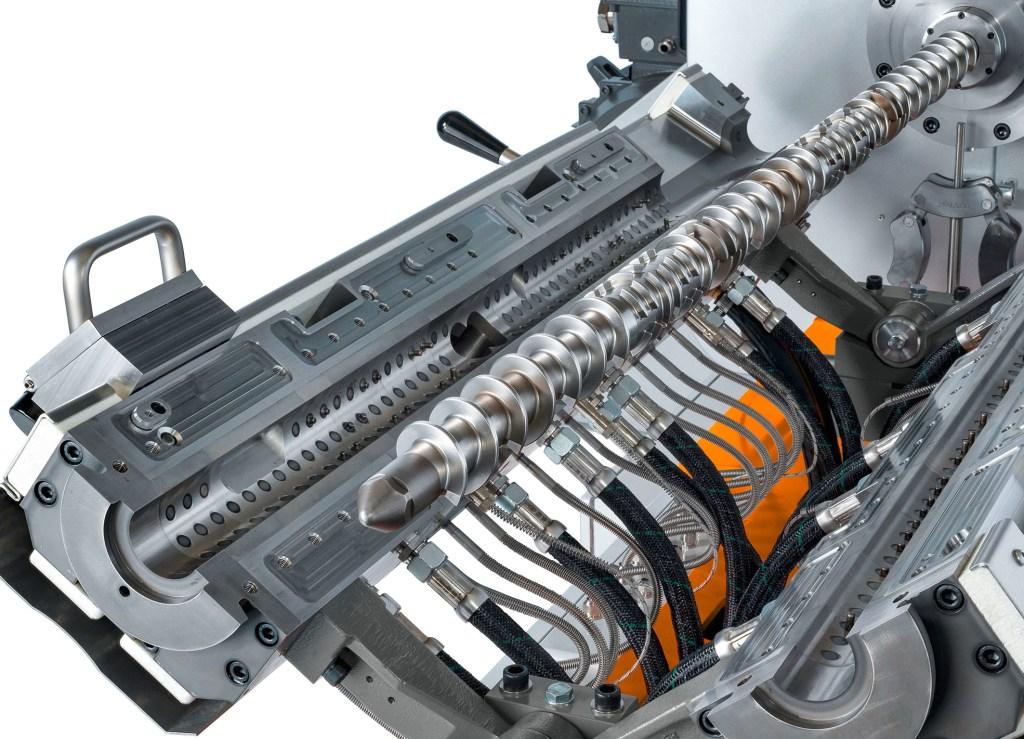

The highly effective and simultaneously gentle mixing action is the result of the particular way the Buss kneader works. Firstly, its screw helix has two to four gaps per turn which give rise to the characteristic flights which mesh with stationary kneading pins mounted in the barrel. Secondly, the screw shaft simultaneously rotates and axially oscillates, performing a complete forward and backward stroke from its starting position per revolution.

The shear required for melting and dispersion arises in the shear gap between screw flights and kneading pins. Based on the working principle, the shear rate is independent of machine size and is directly proportional to the rotational speed of the screw shaft. This explains a further advantage of the Buss kneader technology: the straightforward scalability from lab to production scale. www.busscorp.com

The process chamber of the current generation of COMPEO kneaders, showing the position of the barrel-mounted kneading pins which mesh with the flights of the modular screw shaft

« Back

|