05.10.2020

Technical innovations from Brabender

Brabender Technologie, Duisburg, Germany, has introduced development for the second half of 2020 relating to its bulk materials and liquids feeding, weighing, discharging and flow measurements products. These innovations focus on areas of increased flexibility and safety.

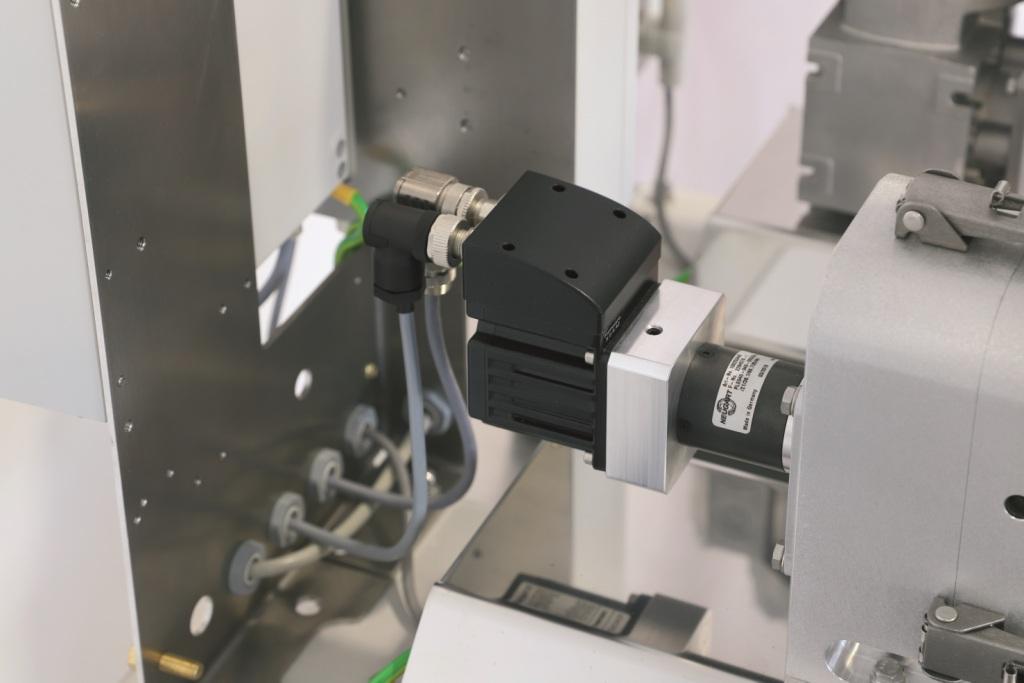

Servo motors will become standard for future feeders. Compared to standard AC motors, the flexible servo drive provides a wider speed range, while maintaining torque: servo motors have the advantage of having their full torque available at low speeds and having negligible speed fluctuations during situations of high torque demand.

Flex connections made from highly durable, tear-resistant liquid silicone rubber (LSR) are essential for sealing upstream and downstream processes. When hazardous ingredients are used, the connections prevent toxic dust from escaping. This new design provides highly flexible characteristics essential for ultra-low feed rates below 50 grams per hour. The flex connection material thickness is specifically designed to be extremely thin in the flexible area and more robust where attached to the clamps.

The recently developed shaft sealing system can be used wherever screw or agitator shafts are required. Brabender has now added a purge system to its innovative radial shaft seal. It consists of an inner pressurised chamber. This means that in the rare event of a seal leak, dust always remains in the chamber. The shaft seals act as a barrier in both directions: on one side towards the motor and on the other side in contact with the ingredient.

The new clear vertical outlet moulded from PETG, is a non-flexible plastic which remains dimensionally stable up to 90°C while being fully sealed. The material is FDA-compliant and is ideally suited for the food industry. As it is transparent, visual inspection of ingredient flow can be carried out at a glance. The clear PETG outlet will be available shortly for the universal FW40 FlexWall® feeder, the twin screw DDSR20 feeder and single screw DSR28 feeder. It will be available for all feeder models and sizes by 2021. www.brabender-technologie.com

Servo motors will become standard for future Brabender feeders

Flex connections made from durable, tear-resistant liquid silicone rubber

« Back

|