|

|

|

|

| News |

19.11.2012

Magnetic separation system for uranium enrichment

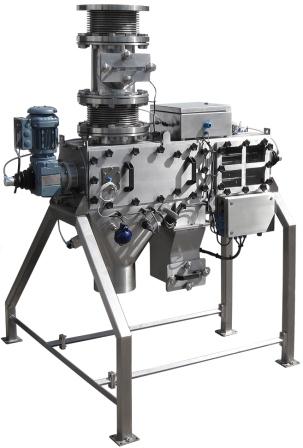

Eclipse Magnetics, Sheffield, UK, recently designed and built a separation system for a leading nuclear fuels company to form part of a uranium enrichment process. In the milling and refining stage, prior to enrichment, uranium is processed in powder form. It is vital that the powder remains completely free from any ferrous contamination. The new separation system had to fit within an existing process without slowing down the operation. High intensity magnetic capability was also vital to ensure that even the smallest ferrous particles were extracted. In addition the uranium powder had a tendency to cake in transit. The unit needed to be fully automated to ensure 24/7 operation as well as to protect workers from coming into contact with the hazardous uranium. ATEX certification was required to ensure zero risk of static build-up and to guarantee the product for use in potentially explosive environments.

Eclipse was able to meet all these requirements by providing a 9000 gauss high intensity, fully sealed Auto Rota Shuttle magnetic separation system with an automated cleaning arrangement which rotates to ensure that the powder is constantly being agitated, thereby ensuring no blockages. The unit was also fitted with sensors to detect flow variations or temperature fluctuations. www.eclipsemagnetics.com

Auto Rota Shuttle from Eclipse Magnetics, specially modified for the needs of a uranium enrichment process

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|