|

|

|

|

| News |

25.11.2013

Lifting jacks for load cell installation rendered obsolete

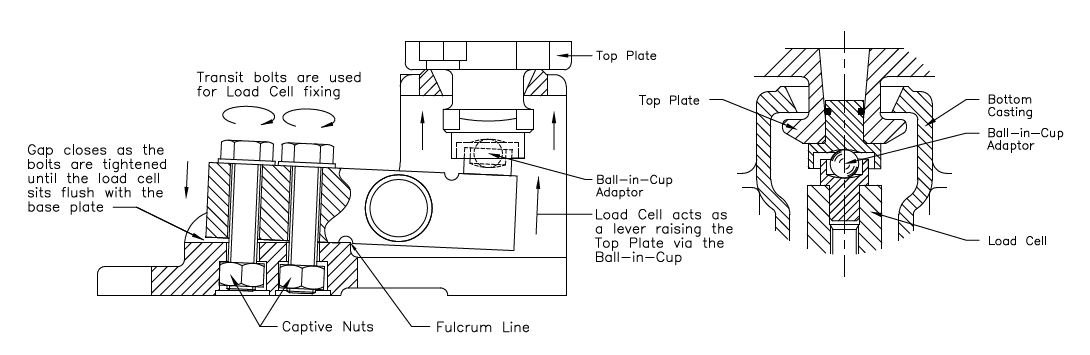

The use of lifting jacks to raise a structure whilst installing load cells is now a thing of the past, according to Thames Side Sensors, Reading, UK. This is thanks to the availability of the company’s LeverMount weigh module. This novel, patented concept allows the weigh module to be attached to the structure during installation, with the load cell still in its box. Once the entire mechanical installation is complete and firmly fixed to the ground, the load cell can be added at the last moment (to avoid damage from any unexpected shocks during installation). Then the cell is fastened down to the weigh module using a simple spanner/socket, which lifts the module by only a few millimetres into the weighing position. This procedure can even be carried out when a storage vessel is full, so processes would not have to stop while a load cell is changed.

At capacities from 10 to 200kg, the LeverMount ‘Lite’ version of the weigh module is compatible with the Model T66 stainless steel bending beam load cell. At higher capacities, from 300 to 5000kg, the LeverMount module is available with the Model 350i stainless steel shear beam load cell. Both of these cells are approved to OIML R60 Class C3, with IP68 / IP69K protection and a high quality polyurethane cable. The LeverMount weigh module ensures substantial lift-off protection and is tolerant of any misalignment in a steel structure. Its three-point attachment to the ground provides high stability as well. Two types of load cell interface can be specified: a load button and saddle arrangement with expansion/contraction adjustment for static applications, and a ball-and-cup (self-centring) option for dynamic applications. Thames Side states that the LeverMount has become the industry standard solution for small capacity hopper and tank weighing, especially in food and pharmaceutical applications requiring all-stainless steel equipment that is resistant to high-pressure wash down and steam cleaning. Dispensing with a screw jack to raise the weigh module eliminates problems caused by threads becoming clogged with powder or dirt. www.thames-side.com

LeverMount weigh module showing ball-and-cup load cell interface

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|