Fike and Hobré form partnership

Fike Corporation, specialists in industrial safety solutions, has partnered with Hobré International, a process analytics company, to improve fire and explosion prevention in industrial drying systems. The collaboration focuses on mitigating the risks associated with spray dryers – common in food, beverage, and pharmaceutical manufacturing -which accounted for nearly 18% of all reported fire and explosion incidents in 2023, according to Dust Safety Science.

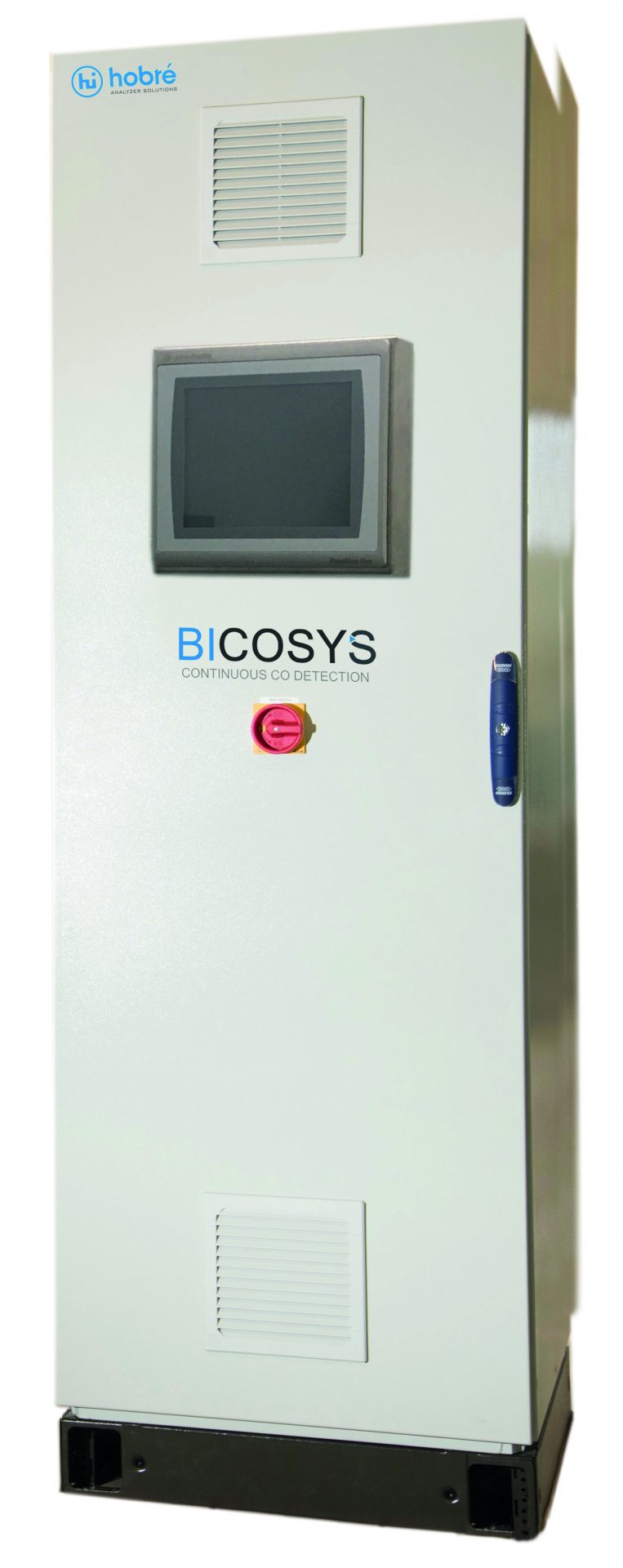

Spray dryers are particularly vulnerable to ignition hazards caused by product buildup and smoldering under high heat. Hobré’s BICOSYS system detects the earliest stages of smouldering by monitoring carbon monoxide (CO) levels, identifying combustion up to 30 minutes before a fire could start. By comparing CO concentrations at both the dryer’s inlet and outlet, BICOSYS helps prevent false alarms while providing accurate, real-time safety data.

“This technology fills an important role in Fike’s explosion prevention efforts,” says Jan-Bart Seymortier, Fike’s Director of Sales, Europe. “Early detection can prevent fires and deflagrations, reducing downtime and protecting both people and equipment.”

The partnership also includes Hobré’s HICOSYS humidity monitoring system, which provides precise control to prevent sticky product buildup – further reducing smouldering risks. Together, the companies aim to deliver integrated safety solutions that enhance reliability and lower operational costs.