Improving contaminant detection

In modern food manufacturing, ensuring product safety through reliable contaminant detection is a critical priority. While single energy x-ray systems have been a mainstay of quality assurance for decades, advances in dual energy x-ray technology – particularly when combined with photon counting detection – are transforming inspection accuracy, efficiency, and sustainability.

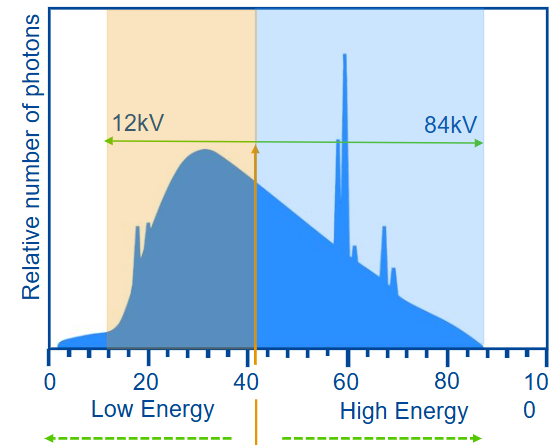

Dual energy x-ray inspection works on the principle of material discrimination. By emitting two x-ray beams of differing energy levels, the system can distinguish between materials of varying densities. This enables more precise detection of difficult-to-identify contaminants such as glass, plastic, rubber, or calcified bone – materials that can often go unnoticed in single energy systems.

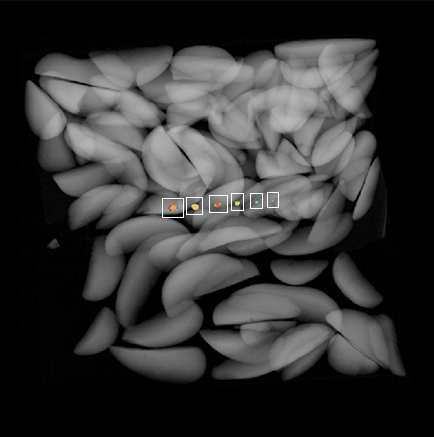

Dual energy systems are particularly effective for products with overlapping layers or varying thickness, such as chicken fillets, frozen potato wedges, nuts, or bags of pasta, where image contrast can make traditional detection challenging.

Photon counting represents a major leap forward in this field. Unlike conventional silicon-based detectors, which first convert x-ray photons to visible light, photon counting detectors – made with cadmium telluride (CdTe) crystals – directly convert each photon into an electrical signal. This eliminates signal dispersion, creating sharper, higher-resolution images with exceptional contrast. The result is a far clearer separation between product and potential contaminants, allowing for the detection of foreign bodies as small as 0.2 mm.

Systems such as Mettler-Toledo’s DXD+ and X36 leverage this technology to deliver pinpoint accuracy, fewer false rejects, and reduced waste – key benefits for operational efficiency. Manufacturers can fine-tune detection without compromising throughput, thereby reducing both recall risks and unnecessary product loss.

Furthermore, CdTe-based detectors enable faster response times and enhanced consistency through electrical splitting of high and low energy spectra, offering superior image clarity over traditional copper-filter systems. When paired with advanced software algorithms, these detectors not only identify contaminants with greater precision but also provide valuable data insights to improve process control and compliance.

To determine the best fit for their production line, manufacturers are encouraged to “Test Before You Invest”, sending real product samples for evaluation under realistic conditions. Generally, dual energy x-ray is most effective when products contain overlapping materials, vary in thickness, or have low-density contaminants and packaging.

Ultimately, dual energy x-ray inspection – empowered by photon counting technology – sets a new benchmark for food safety. By improving detection sensitivity, minimising false rejects, and optimising operational efficiency, it enhances both product integrity and business performance. In an industry where every fraction of accuracy counts, these advancements deliver measurable value – protecting consumers, safeguarding brands, and ensuring manufacturers remain competitive in increasingly demanding markets.

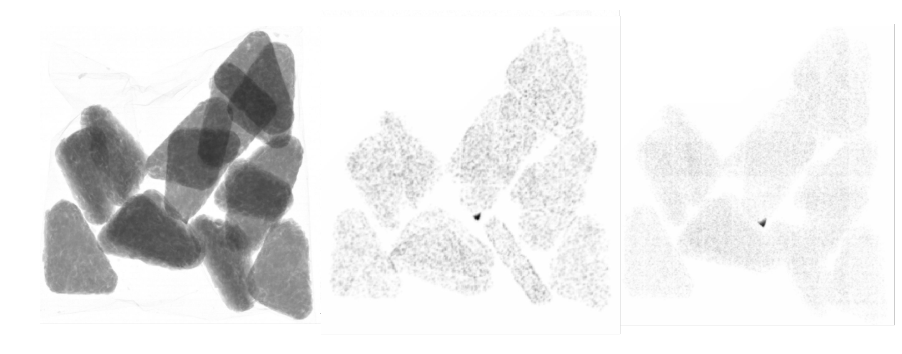

The three images illustrate different x-ray imaging techniques: on the left, Single Energy imaging, which captures x-ray data at one energy level; in the center, Dual Energy imaging, which utilises two distinct energy levels for enhanced contrast and detail; and on the right, Photon Counting Dual Energy imaging, which counts individual photons to provide even greater precision and clarity in the resulting images.

This image displays the x-ray spectrum emitted by an 84KV Beryllium generator, illustrating the energy range and highlighting the optimal split for a certain product. The graph provides insights into the distribution of energy levels, showcasing the characteristics of the emitted x-rays and how they are categorised for analysis.

Mettler-Toledo dual energy technology can detect six pieces of 2mm rubber contaminants in a pack of potato wedges. This advanced detection capability enhances food safety by identifying foreign objects that may pose a risk to consumers, ensuring higher quality and safety standards in food products.