Patent granted for “Optimised Grind Finishing” process

Bolz Intec GmbH has achieved a major milestone in stainless steel surface technology with the successful patenting of its Optimised Grind Finishing (OGF) process. Developed in collaboration with the University of Konstanz, this breakthrough marks the culmination of several years of intensive research and innovation.

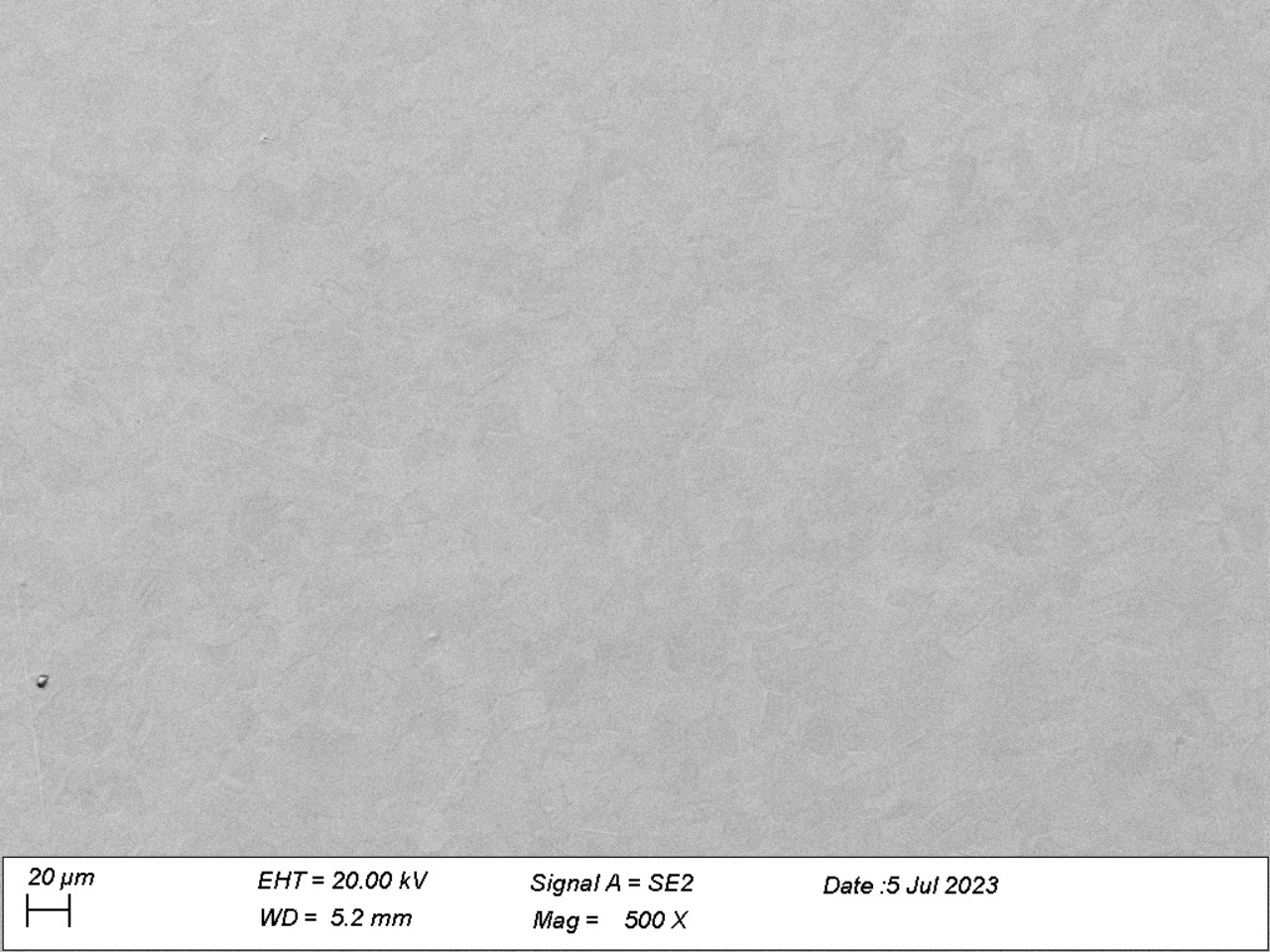

The OGF process significantly reduces particle adhesion on stainless steel surfaces, minimising the risk of product contamination and improving the integrity of sensitive manufacturing processes in industries such as pharmaceuticals, cosmetics, and fine chemicals. Enhanced surface cleanability also allows for reduced use of cleaning chemicals, abrasives, water, and energy – delivering both performance and sustainability benefits.

“Patenting the OGF process represents the successful completion of a long-term innovation project that unites technological precision with environmental responsibility,” said Cornelius Mauch, Managing Director of Bolz Intec. “Our cooperation with the University of Konstanz was instrumental in creating a solution that offers enduring ecological and technical value.”

Producing high-precision, metallically pure surfaces with defined roughness, the OGF process ensures exceptional process reliability. It is already being applied to the manufacture of stainless steel containers, funnels, and custom components for leading global pharmaceutical companies, setting new standards in surface innovation and industrial sustainability.

Cornelius Mauch, CEO Bolz Intec GmbH

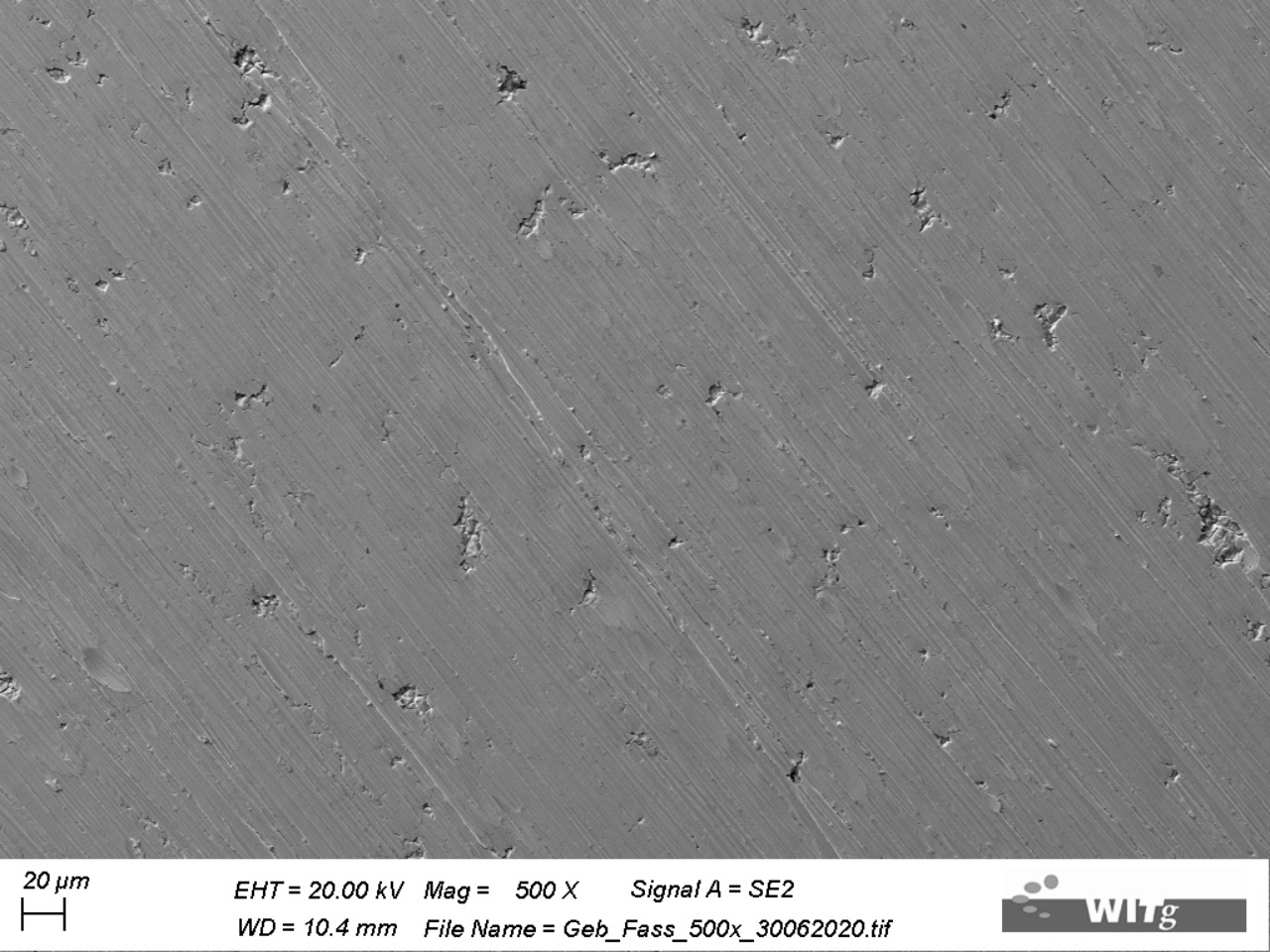

Bolz Intec Stainless Steel Drum

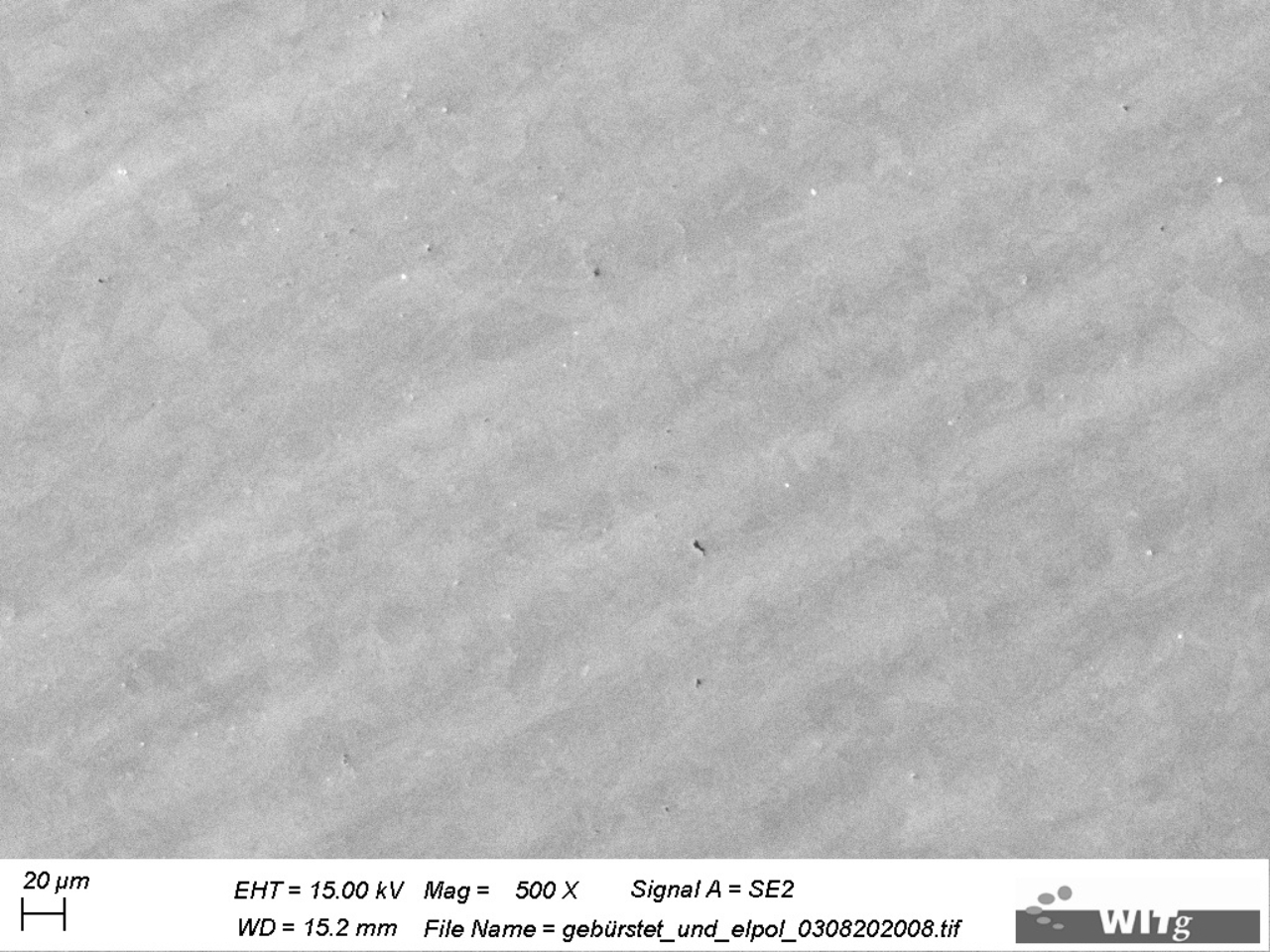

Stainless steel surface brushed REM

Stainless steel surface brushed and electropolished