Lindner unveils Flexloop high-purity mechanical recycling

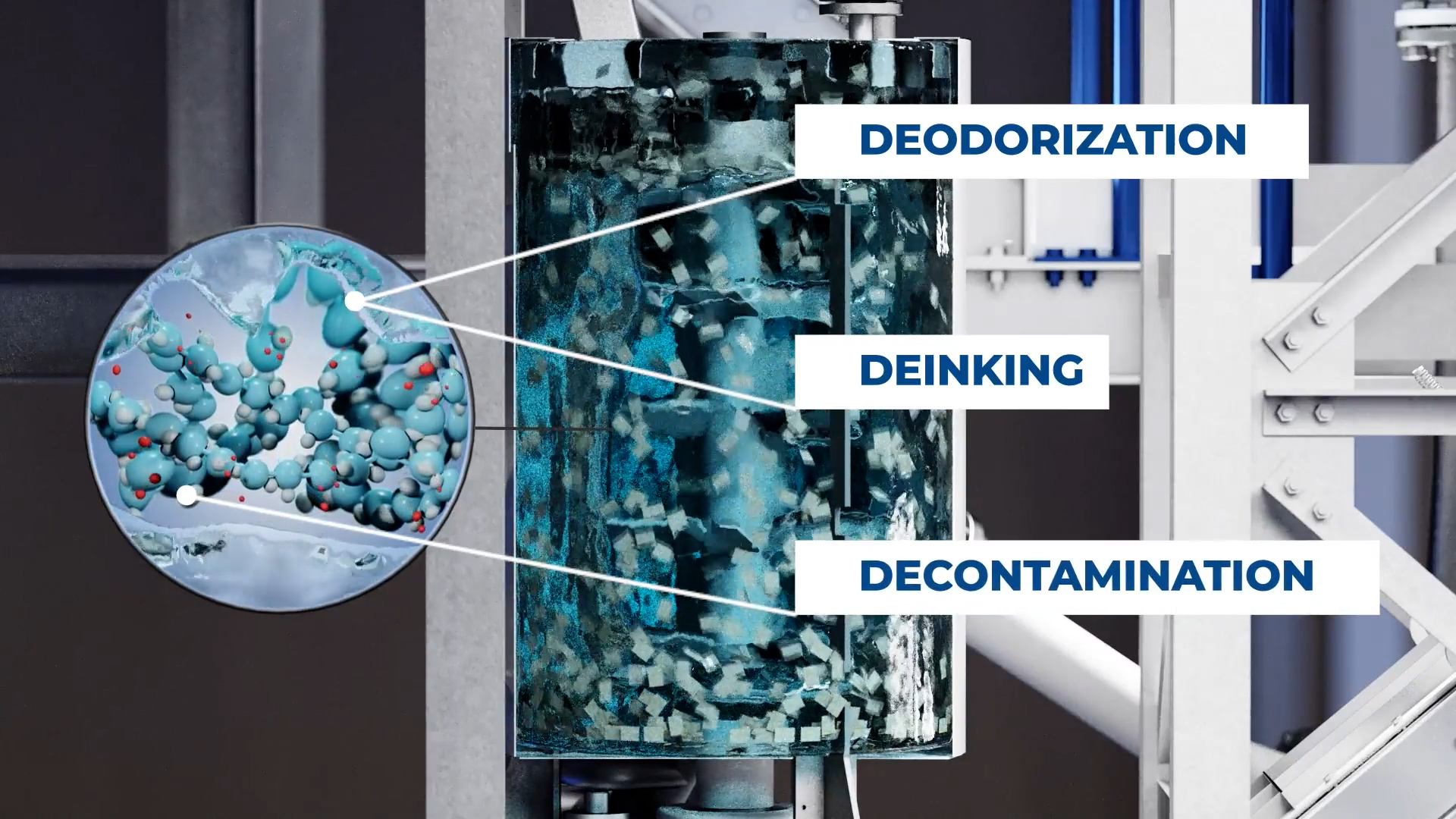

Lindner has introduced an important initiative in mechanical recycling with the launch of Flexloop, a pioneering solvent-based cleaning technology developed in partnership with Procter & Gamble. Revealed for the first time at K 2025, Flexloop delivers a high level of purity in post-consumer recyclate by extracting non-intentionally added substances (NIAS), odours, adhesives and printing inks from polymer chains. The result is high-quality material suitable even for sensitive packaging applications in sectors such as cosmetics and personal care – traditionally the domain of virgin plastics or chemically recycled feedstocks.

The innovation stems from initial discussions between Lindner and P&G at the previous K show, evolving into an exclusive licensing agreement and a joint objective of creating an industrially scalable process. “For us, Flexloop is a logical and necessary development in mechanical recycling,” says Michael Lackner, Managing Director of the Lindner Group. Positioned as an extension of established cold and hot washing lines, Flexloop adds a powerful solvent-based extraction step that removes deeply embedded contaminants – including pesticides, phthalates and dioxins – without degrading polymer structure.

For recyclers, this addresses a long-standing challenge: contamination from mixed post-consumer waste streams. As Yannick Stanau of Lindner Washtech explains, NIAS can diffuse into packaging during collection and sorting, limiting recyclate to lower-value applications such as refuse bags. Chemical recycling offers an alternative but remains commercially prohibitive due to high energy and investment requirements.

Flexloop bridges this gap. By enabling consistent, high-purity recyclate, it meets stringent regulatory and brand-owner specifications while preserving the familiar mechanical recycling framework. P&G’s leadership emphasises the process’s potential to scale high-quality rPE and other film grades for fully circular packaging. “This innovation helps address environmental challenges and supports a circular economy for materials,” notes P&G’s Lee Ellen Drechsler.

Designed as a modular unit, Flexloop integrates into existing Lindner washing and recycling lines, enabling recyclers to upgrade capabilities with minimal capital expenditure. “Target users can simply retrofit their existing washing lines,” adds Gian De Belder, P&G’s Technical Director for Packaging Sustainability.