13.04.2020

Dosing dextrose: a switch from food to pharma/cosmetic applications

TMI (Técnicas Mecánicas Ilerdenses), Lleida, Spain, the specialist manufacturer of bagging and palletising systems, recently collaborated closely with one of its customers: an important producer of dextrose for the food sector who wished to adapt part of its plant to produce dextrose for pharmaceutical and cosmetic usage. These are industries requiring strict hygiene measures with which the bagging machinery also needed to comply. One of TMI’s main goals from its beginning has been to cooperate fully with the customer, not just as a mere supplier but as an advisor and a trusted ally.

Glucose is a fine cohesive product which tends to lump and release powder. Previously, this customer used a weighing system with gravity dosing which, apart from releasing large amounts of powder all around, also tended to fluidise the product, adversely affecting dosing and weighing accuracy. The dosing system needed to be improved in order to provide a clean environment and accurate filling of the bags.

Furthermore, the configuration of the existing hopper caused irregular flow: the slant of one of its sides led to product dispersion so that larger particles settled first at the bottom of the hopper and thence to the screw extractor. Thus, the finest particles would stay in the upper part of the hopper preventing a homogeneous mixture of the final product.

Moreover, the weighing and dosing system was placed two floors above the bagging spout in a clean room environment with an external palletising system. This was one of the critical factors when designing this equipment: the existing layout had to be retained, while fulfilling the strict hygiene measures required for a pharma product.

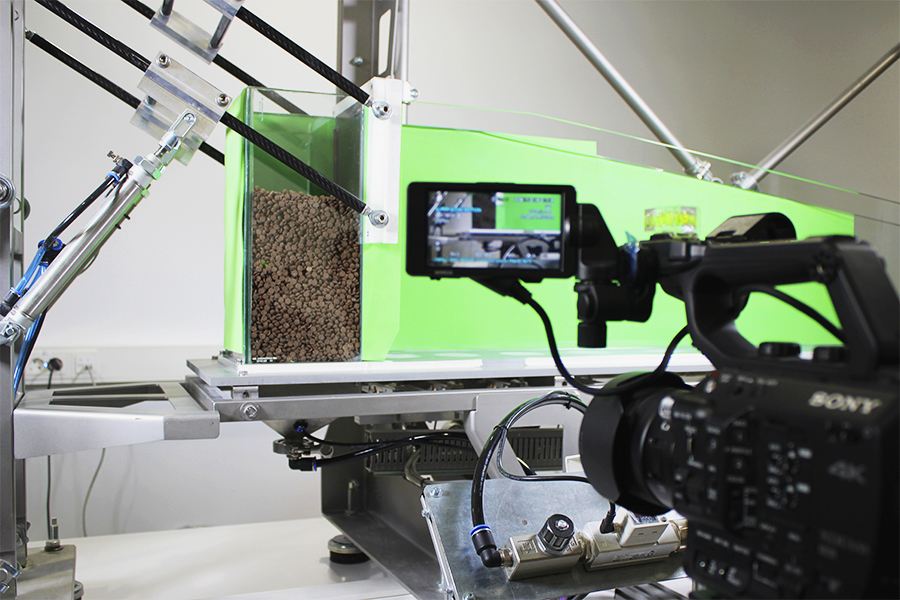

Both technical and empirical approaches to the project were decisive: TMI has a test laboratory capable of simulating material segregation, thereby typifying the product behaviour and preventing critical dosing problems. This resulted in the current design of the weighing system, which fulfils the following criteria:

- Quick and easy cleaning process: a screw detaching system has been incorporated, allowing the screw to be emptied at every end of cycle, with residual product recovered into a joint collection tray. Furthermore, this detaching function facilitates the hygiene process for the operators, who can easily access the area to be cleaned with this tool-free detachable unit.

- Controlled dust-tight dosing: the bagging spout has been adapted with an optimised opening for better shut-off. New aspiration and compression points have been strategically installed. www.tmipal.com

Particle segregation tests at TMI’s test plant

« Back

|