|

|

|

|

| News |

27.07.2020

Continuous conveying and dosing of powders

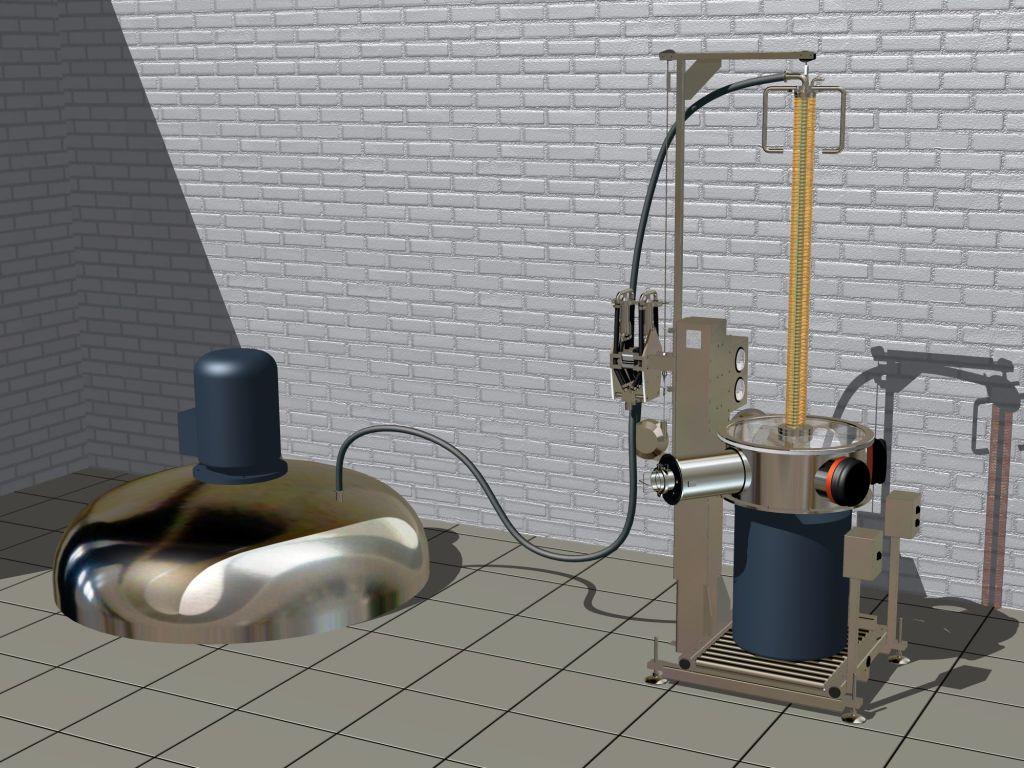

Dec Group (Dietrich Engineering Consultants), Ecublens, Switzerland, reports growing success with its patented PFL Powderflex for applications involving continuous conveying and precise dosing of small to medium quantities of powder. Here the requirement might be for controlled charging of powders into a continuous production process or for predetermined precision dosing. This technology was initially developed for the plasma and spray coating industries but is now used for a multitude of applications. The company states that the PFL Powderflex is to powder what a peristaltic pump is to liquids.

PFL extracts powder from any container and conveys it over large distances (> 50m). Its simple design ensures minimal maintenance thus facilitating rapid product changes. Powder characteristics are not modified during the transfer.

The system comprises two small, calibrated chambers, each equipped with a flat filter in the upper part. A practically continuous powder flow or precise volumetric dosing is generated through a unique valve system. The combined effect of vacuum and pressure alternately fills and empties the chambers at a high frequency.

Typical transfer capacities vary from a few hundred grams to 200kg/h and can be easily adjusted automatically. The system can handle explosive powders and feeds equipment under pressure or vacuum. Powderflex is easy to clean and allows for CIP procedures. www.dec-group.net

Dec Group’s PFL is attached to the DCS® drum containment system and transfers powder directly from drums into the reactor under high containment

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|