03.08.2020

Novel conveyor belt skirting concept

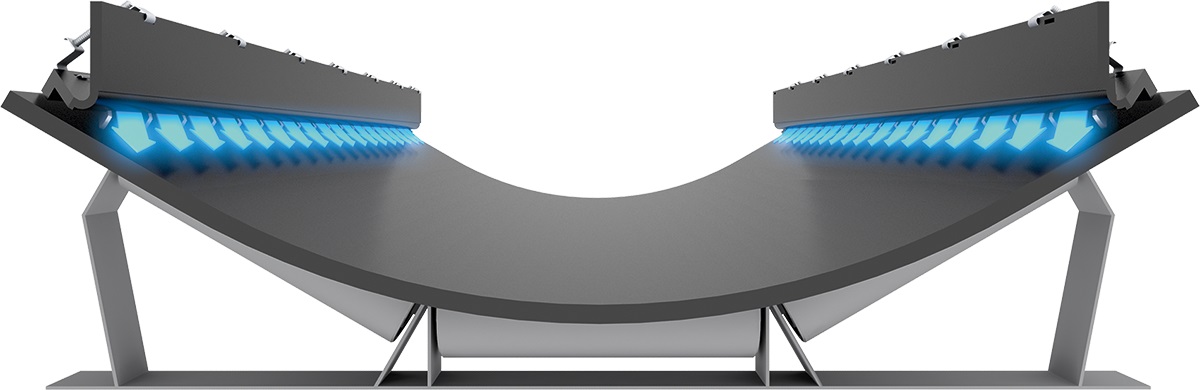

ScrapeTec Trading, Kamp-Lintfort, Germany, has launched the contact-free AirScrape® conveyor belt skirting system, which has been designed to significantly reduce material spillage, dust formation and explosion hazards at transfer points and other critical sections in the conveyor chain. Because this system hovers freely above the conveyor belt, skirt friction and belt damage are eliminated and service life is extended.

“The AirScrape system – which encompasses inward facing, hardened-steel diagonal blades – operates according to a new principle whereby it hovers 1-2mm, on the left and right side above the conveyor belt. These blades deflect larger particles inwards, while using the air-flow of the conveyor belt and conveyed material to create an inward suction, directing any dust and fine particles back into the product flow,” explained Thorsten Koth, sales director of ScrapeTec-Trading. “Through these diagonally fitted blades and the speed of the running belt, air is drawn from the outside inwards. As a result, neither the dust nor material can escape.

“Conventional skirting is pressed against a conveyor belt to keep dust and material in the middle of the belt, but after a period, wear of the skirting and belt can be so severe, that material and dust escapes. Material spillage at transfer points needs to be removed and regular maintenance of belt skirting and transfer points is necessary.

“With the AirScrape dust-free and contact-free, side sealing system for belt conveyors, there is no skirt contact and therefore no belt wear or damage. Motor power requirements are reduced as there is no belt-skirt friction and because there is continuous skirting with no gaps, product loss is minimal.

“Studies show that even three years after installation and with continuous use in harsh conditions, the AirScrape system hardly shows any signs of wear. Operational costs are also reduced because there is no need for spillage collection, regular maintenance, or replacement parts.”

This system is available in pairs of left- and right-hand 2m, inter-connectable pieces, to form any required length and is available in different base widths of 100mm and 55mm, to suit various belt widths and chute sizes. For flexibility on site, this system is completely extendable. www.scrapetec-trading.com

Because the AirScrape system hovers above the moving conveyor belt there is no skirt contact and consequently no belt wear or damage

« Back

|