03.07.2023

Beumer: “Rethinking the machine”

The Beumer Group has completely redesigned and overhauled its paletpac range of palletizers. The modular machines now have identical or similar components and modules and – wherever possible – are based on the same design. The total number of components has been reduced and faster deliveries are possible. If replacement parts are later needed, this will also go faster. Beumer configures the modules according to each customer’s requirements, tests them in-house and installs them on the customer’s premises, saving time and money.

The new model range not only makes configuration easier, it also simplifies installation. “Previously, it was necessary to use forklifts with a capacity of up to eight tons,” says says Kay Wieczorek, Divisional Director of Product Business. “Now a capacity of five tons is sufficient.” The modules are designed so that they can be picked up from two different sides. This simplifies assembly in confined spaces. Customers formerly received two large modules; now they get three that are more compact, which makes handling simpler. We now only need standard shipping containers.”

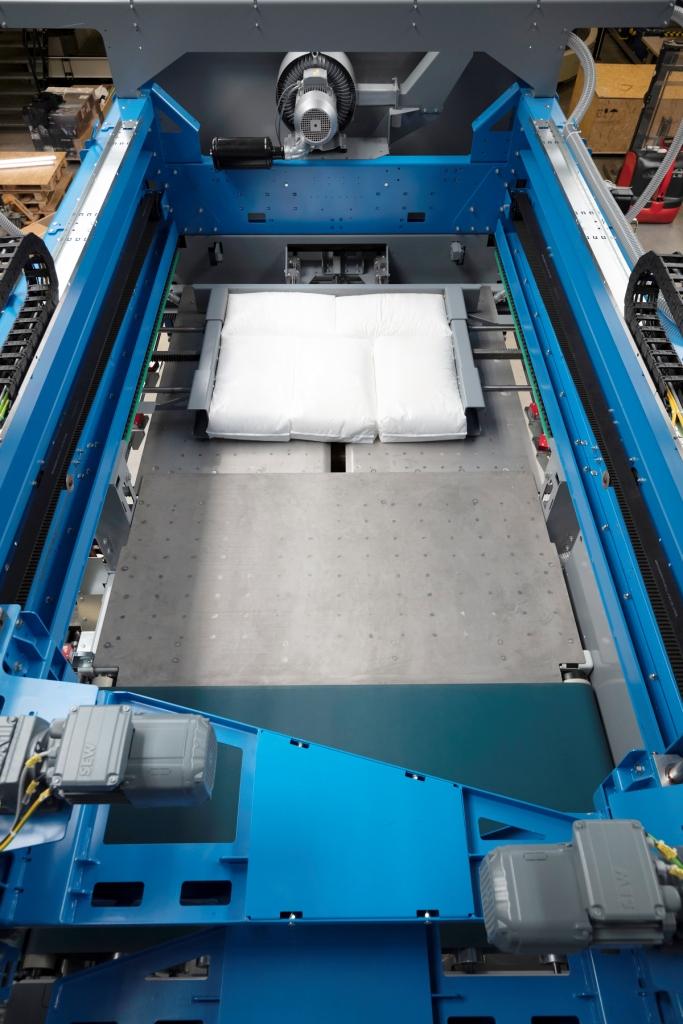

The new Beumer paletpac has been equipped with a larger deposit table. With maximum layer dimensions of 1,500 x 1,300 millimeters, it can accept bags filled with bulk materials on euro pallets or pallets with other formats.

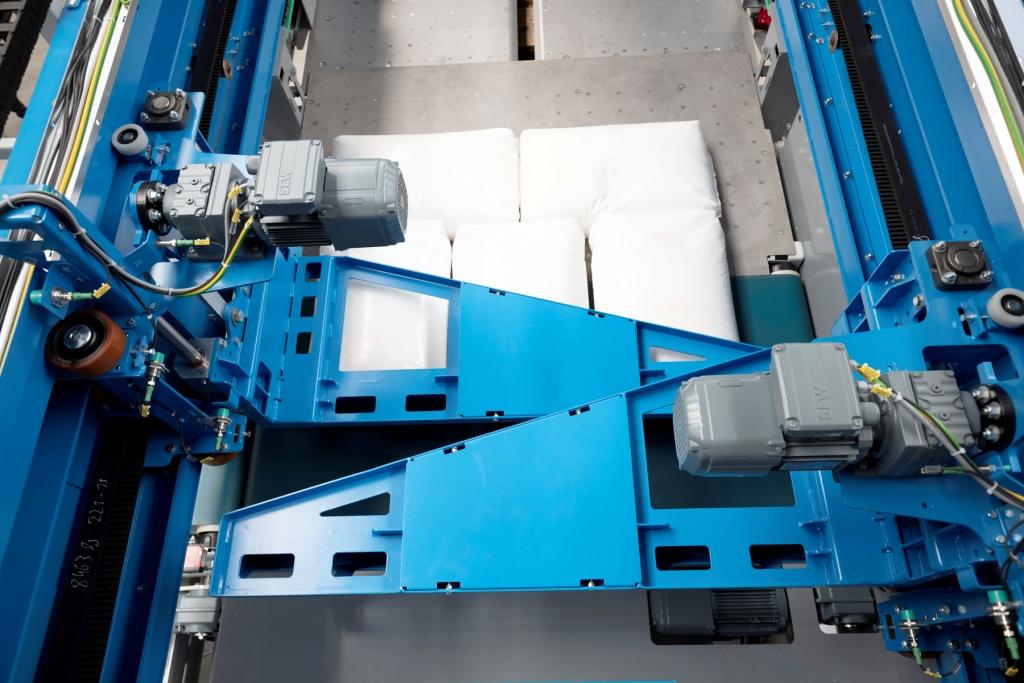

The developers have also redesigned the pusher, which is used in all Beumer paletpac models. The undercarriage is the same for both single and double pushers, enabling users to increase the performance of the system at a later time without making big adjustments to the modules.

When they modernized the paletpac, Beumer’s developers also improved its footprint. The control cabinet bays have a standard configuration, but a space-saving offset arrangement is also possible if required by the customer. The enclosure for the lifting gear also saves space. “We gave this series a slim design,” explains Wieczorek. The Human Machine Interface (HMI) is located on the maintenance platform at the layer preparation level. If the operator needs to make adjustments, he or she can see the whole machine at once. Additional control units, for example in the area of the lifting gear, can optionally be installed for even greater convenience.

For drive technology, the Beumer paletpac relies on the MOVI-C modular automation system from SEW. This centralized approach requires less space in the control cabinet and reduces the number of components in the bay. Energy savings of 20 to 30 percent can be achieved by means of a common DC link in the frequency converters and optimized motion sequences. Energy storage units are another option: “These are an efficient means of eliminating peak loads. They also cut operating costs for users and reduce the carbon footprint,” says Wieczorek.

www.beumer.com.

(Top) The Beumer paletpac series is keyed to the characteristics of the packaged goods and complies with the customers’ requirements for packing patterns and pallet dimensions.

(Middle) The new Beumer paletpac with undercarriage for a single or double pusher. Layers with dimensions up to 1500 x 1300 millimeters can be prepared and pushed to the deposit table.

(Bottom) The lifting gear of the Beumer paletpac in action. With cement, for example, the machines can achieve a throughput of up to 6,000 bags per hour.

« Back

|