04.09.2023

Energy-efficiency technology on show

The energetic saving potential of more efficient process technology is the focus of German machine and plant manufacturer ystral’s booth at Powtech 2023.

ystral projects, designs and manufactures mixing, dispersing and powder wetting machines as well as process systems, for use in the chemical, pharmaceutical, coatings and inks, foodstuffs, home and personal care as well as battery production industries. The theme of ystral’s trade Powtech show presentation is the reduction of energy demand through more effective process technology.

“Compared to conventional solutions such as high speed dissolvers or agitators, innovative mixing and dispersion technologies achieve significant improvements – depending on the application, the energy demand can be reduced by up to 90%”, says Dr.-Ing. Hans-Joachim Jacob, Senior Expert Process and Applications at ystral. “At Powtech, we would like to enter discussions with users about where they need to start to markedly lower their energy demand and overall production costs.”

By means of process intensification and an implementation of intensive processes outside the vessel, ystral achieves significant process time reductions compared to conventional technologies, which significantly reduces the energy requirement even in case of a higher power input. On average, processes with a ystral disperser for powder induction and a ystral Jetstream Mixer in the vessel save about two-thirds of the energy previously required.

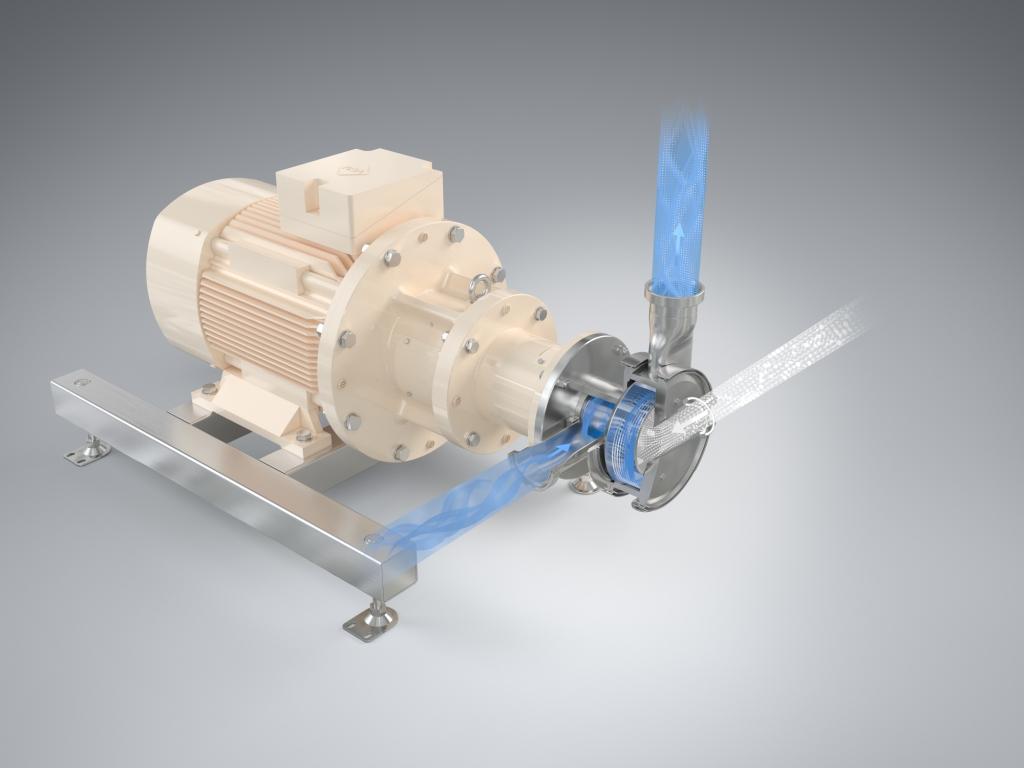

ystral will be exhibiting the ystral Conti-TDS powder wetting and dispersing machine in the two sizes Conti-TDS 2 and 3. In the Conti-TDS, the processes of wetting and dispersing are concentrated in a dispersing zone with an effective volume of only about a quarter of a litre. Compared to a dissolver operated in a vessel, the disperser generates about 30,000 times higher volume-specific power, which is crucial for successful dispersion. Using a rotor-stator system, the disperser also builds up shear forces that are a thousand times higher. The dwell time is extremely short, so that only a fraction of the energy is needed compared to the High Speed Dissolver.

The Conti-TDS 2 powder wetting and dispersing machine will be displayed, together with a Jetstream Mixer as a compact process system. The Conti-TDS 3 disperser will be presented together with an ystral Jetstream Mixer, a textile silo and the ystral Flex FSA discharge aid for poorly flowing powders as a complete process system. In addition, the ystral Multipurpose unit with the X100 tool shaft will be presented. By simply exchanging the shafts, ystral Multipurpose systems can realize different tasks such as jet mixing, mix-dispersing, dispersing and wetting powders with only one system.

www.ystral.com

ystral projects, designs and manufactures mixing, dispersing and powder wetting machines as well as process systems

(Below) The ystral Conti-TDS powder wetting and dispersing machine

« Back

|