23.10.2023

Efficient process technology for dogs and cats

The demand for veterinary products is increasing worldwide – and with it the need for efficient, hygienic manufacturing processes for products such as chewable tablets.

From a technical process point of view, such chewable tablets mainly consist of dry raw materials: In the basic recipe, Active Pharmaceutical Ingredients (APIs) or other additives, such as vitamins or flavours, are added to a basic product (e.g. corn starch or protein powder). The first intermediate product is thus a powdery dry mixture.

After this premixing, liquid components such as liquid polymer (PEG or macrogol) or oils (such as soya oil, fish oil) are added and incorporated in a second step. At room temperature, however, these liquids can harden or crystallise in contact with the mixer or the mixed material before they are completely distributed. Therefore, both the mixer and the dry mix must be tempered beforehand. Usually it is heated to around 50 to 60decC, to optimise distribution of the added liquid components in the dry mixture.

After another mixing process, a very pasty, marzipan-like dough is formed. After emptying the mixer, the mixture is transferred to a moulding machine as a lump or dough strand. Finally, the formed tablets are baked through and packaged.

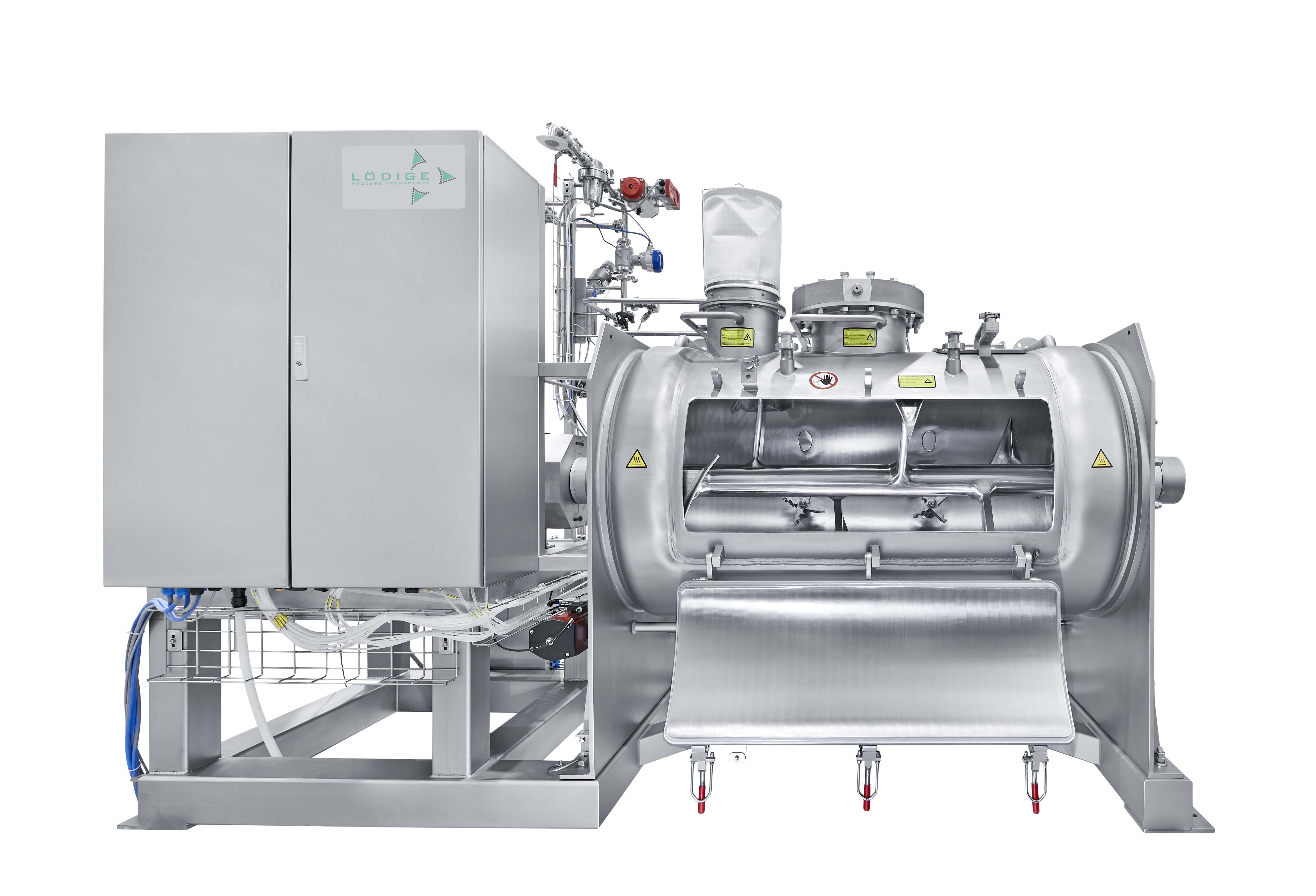

Both mixing steps take place one after the other in the same machine and in batch operation. Ploughshare Mixers FKM from Lödige Process Technology, with 600 to 3000 litres nominal volume, operate based on the mechanically generated fluid bed that ensures a good mixing performance. It was introduced to industrial mixing technology by Lödige: the specially developed shovels rotate close to the wall inside a horizontal drum, creating the fluid bed. The process enables a high degree of homogeneity and constant reproducibility.

Ploughshare Mixers come in various different sizes and are also available in an explosion protected version for specific applications. The customer-specific design of machines and machine lines is just as much a matter of course as strict adherence to all current GMP directives and FDA regulations, which also apply to the production of veterinary pharmaceuticals.

However, Lödige does not only supply the mixer(s). As a solution provider, the company also implements entire machine lines.

www.loedige.com

Ploughshare Mixers can meet the specific requirements for the production of chewable tablets for dogs and cats

« Back

|