|

|

|

|

| News |

06.11.2023

How can ultrasonics benefit the production process?

Adding ultrasonic capabilities to your industrial sieving processes can improve separation accuracy and offer a more efficient material flow, especially when handling powders, says Stephen Harding, managing director at Gough Engineering.

Ultrasonic vibrations, made up of inaudible soundwaves, are created by a special generator and converter that are connected to the edge of the mesh frame of the sieve. The high frequency waves then vibrate the screen to provide additional stimulation in the production process. This is especially effective when handling fine powders or delicate ingredients.

“While a Gough Engineering sieve can break up any agglomerates or clumped material at its point of input into the production process,” says Harding, “adding ultrasonics to this process takes the level of separation one step further.

The mesh within the sieve will be tailored to the customer’s inputs. However, the addition of the Gough Engineering Ultrasonics package means that the high frequency sound waves break up blockages and increase throughput and material flow. This keeps screens very easy to clean, and further minimises any downtime.

Ultrasonics can be used in combination with screens sized between 50 and 200 microns. This makes Gough Engineering’s Ultrasonics Package ideal for fine powder applications, says Harding.

With ultrasonics, one should expect to see:

• A higher sieving throughput

• No pegging or blockages of the apertures in the screen mesh

• Superior separation accuracy of the sieved product

• A reduction in system downtime

• More efficient material flow

www.goughengineering.com

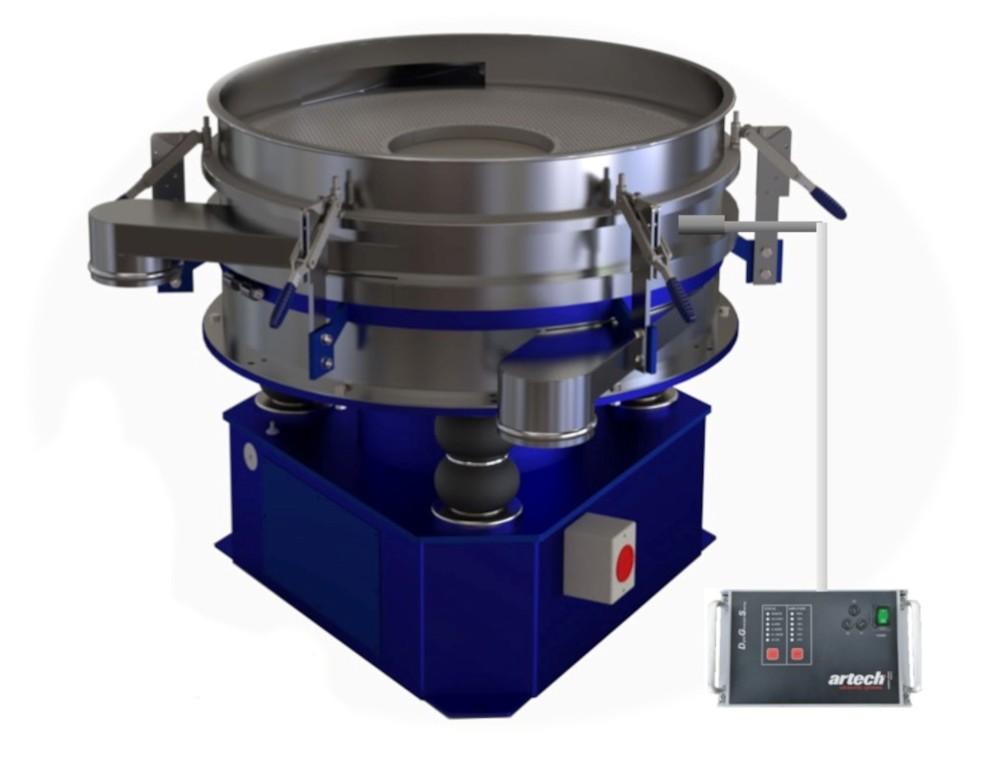

An ultrasonic screening system, shown here attached to a Gough GV550 Batch Sieve, comprises a generator, a converter and a matched screen resonator with screen frame.

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|