Rotary valves for corrosive atmospheres and abrasive products

Rotary valves are vital components in bulk solids handling, serving to discharge, convey, and isolate materials while maintaining pressure differentials. They also function as safety devices – acting as flame and explosion barriers in hazardous environments.

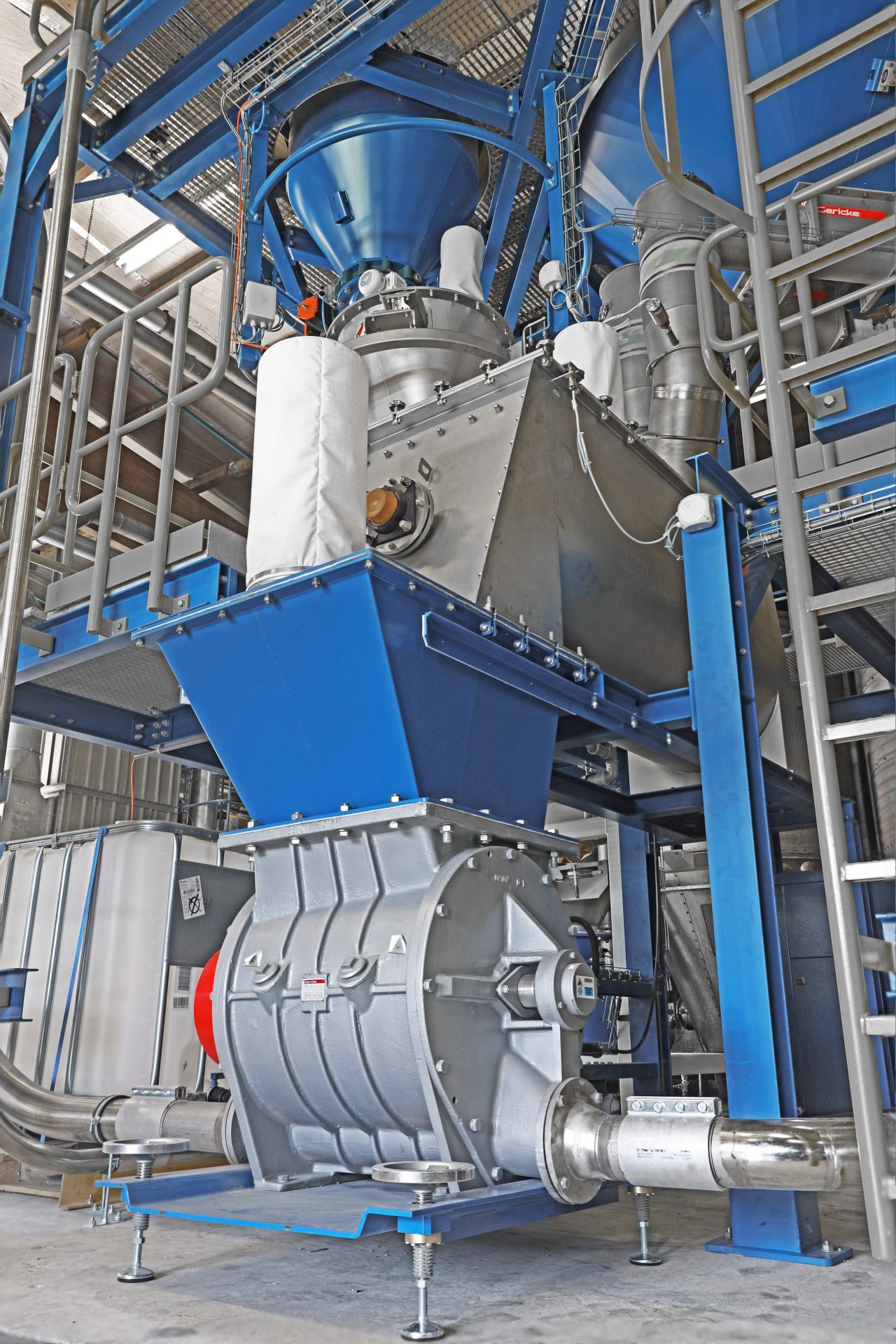

In the petrochemical and chemical industries, rotary airlock valves are essential for transferring bulk solids such as catalysts, resins, and polymers under demanding conditions. These applications often involve abrasive or corrosive materials, requiring valves built with robust construction, wear-resistant coatings, and corrosion-proof materials to ensure long service life. Gericke RotaVal designs and manufactures rotary valves up to 600 x 1200 mm, offering custom solutions for high throughput and large particle sizes.

Beyond metering and feeding, rotary valves maintain process integrity by preserving pressure differentials between zones such as silos, reactors, and pneumatic conveying lines – preventing gas leakage, contamination, and potential hazards. Options such as explosion-proof motors, high-temperature seals, and easy-clean designs enhance safety and reliability.

Gericke rotary valve in chemical application

Gericke RotaVal up to 600 by 1200 mm